Laser characterization & chip testing

An important aspect of the development and manufacture of laser diodes is the so-called laser diode characterization, or Laser IV curve. By applying current to the laser diode so it that emits light, the optical output is measured together with the voltage drop across the diode element as a function of increasing current. The resulting LIV curve reveals important clues as to the quality of manufacture and the performance of the laser diode, enabling a pass/fail decision to be met.

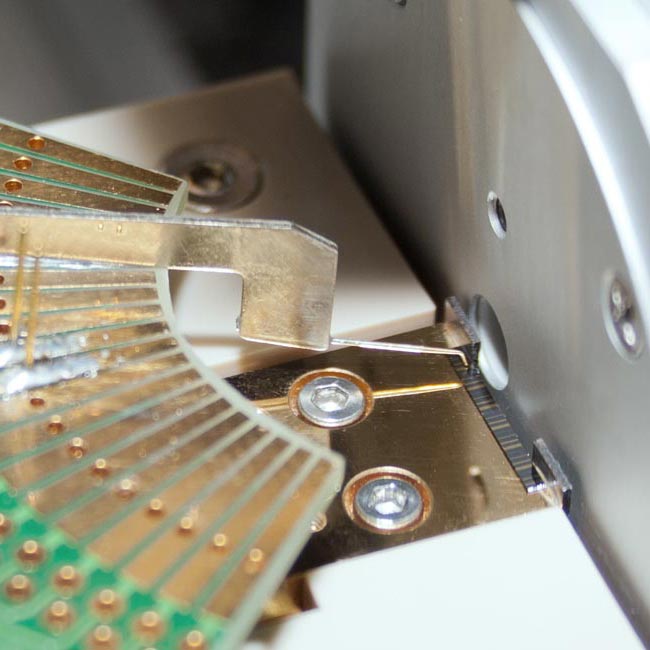

To test if all functional components are meeting specifications, they can be tested with an automatic test system from ficonTEC’s test line. The characteristic laser parameters are measured by running an LIV or a DC sweep. Parallel to the optical power, the optical output spectrum and near and far-field characteristics can also be measured.

The accumulated data is written to a SQL Database, providing the user with the necessary statistical analysis and feedback so that e.g. yield can be improved. The systems allow full component tracking and sorting when equipped with a handling system.

Key capabilities

-

Pick-&-place of high-power laser diodes

-

Single chip, or parallel testing of entire bars

-

Optical beam characteristics can be measured in parallel with optical power

-

All acquired and statistical data written to SQL file automatically

Key features

Vacuum pick-up tool handling

LIV, spectral and far & near field tests

Fully automatic handling of devices

Easy to change probe head

Option for component top side and facet inspection

Flexible integration of external test algorithms and test systems

Compatible to SQL and other database systems for data traceability

More information

Relevant machine platforms and associated modules and technologies:

Chip testing : TL2000