Photonic Device Assembly

Assembling the photonic devices that enable other industry sectors to move forward

Although the lion’s share of photonic device assembly is still for discrete components and devices, the recent developments in photonics integration illustrate well the ensuing dramatic evolution of the photonics market. In transitioning from the use of bulky macro-systems to micro-optical components to integrated optics, the photonics sector is experiencing what has become true for the electronics market since the 1970’s.

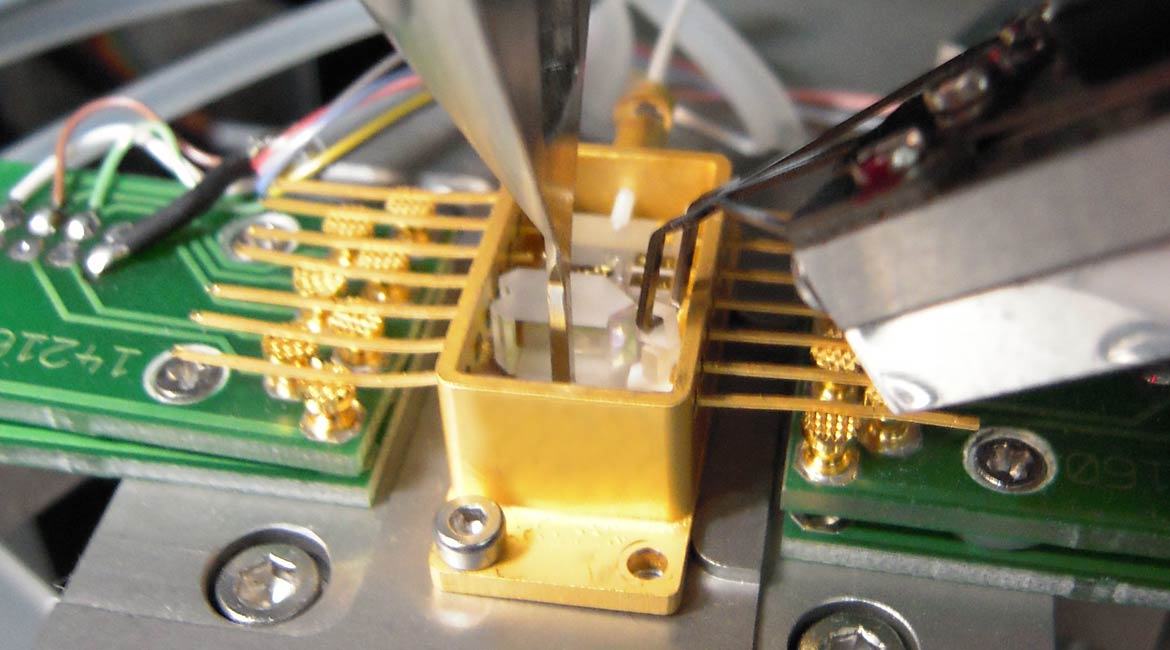

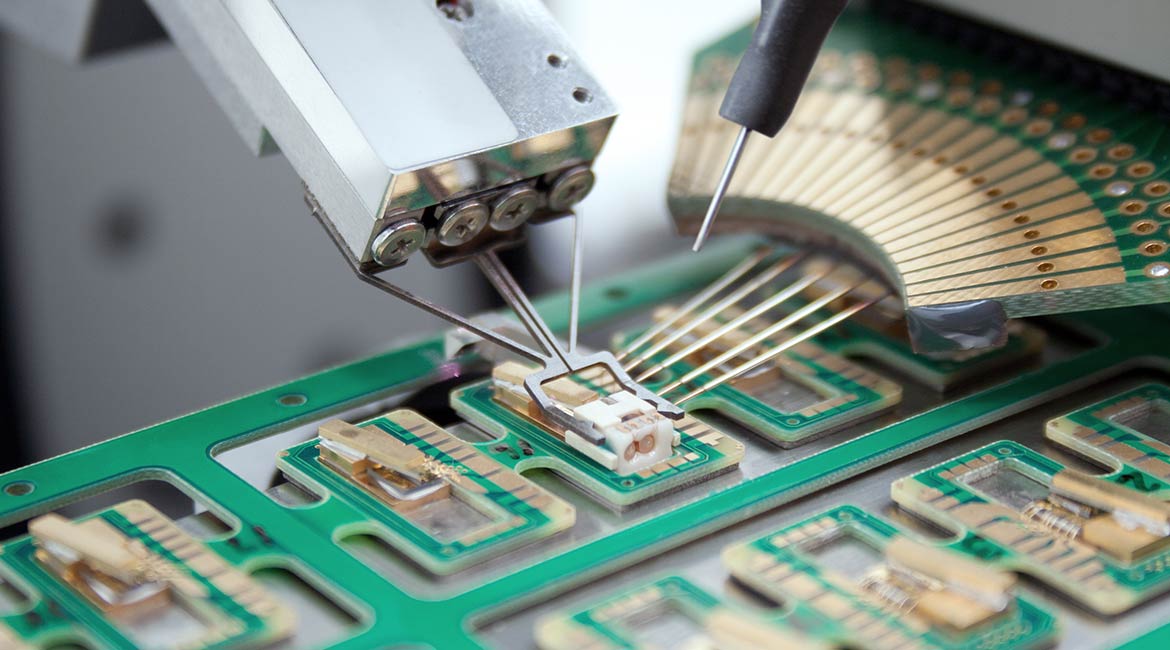

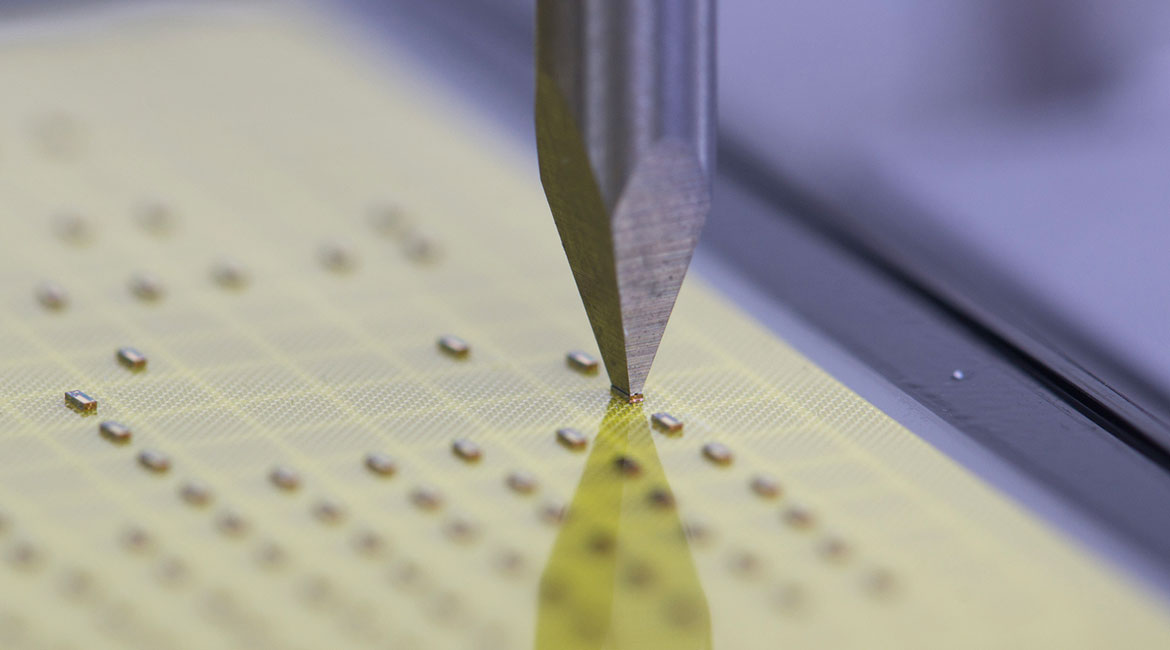

Irrespective of component size, the assembly of photonic devices still fundamentally depends upon precision positioning and alignment. Additionally, a high-precision and thermally capable bonding approach is key to the absolute performance and long-term reliability of the assembled component, as it directly affects lifetime (via heat dissipation) as well as operation and performance (via component temperature or residual stress). And by properly accounting for shrinkage during bond cooling or curing, maximum performance can be assured, thus maximizing yield.

As the component density of optical modules and their complexity increases – a vital trend necessary to ensure the future competitiveness of photonic solutions – the need for advanced automation in assembly becomes increasingly obvious. And in particular when hybrid integration with semiconductor electronics is required – where electronics manufacture is already a highly automated technology – automation of photonic device assembly is the only real way forward.

The photonic devices our machines assemble include silicon photonics components, (3D) sensor and lidar assemblies, photonics-enabled medtech devices, MEMS/MOEMS, miniature lasers, HPLDs and fiber pump modules, hybrid assemblies, LED print heads, high-power LEDs, optical communication devices, and many more.

Have a device type that is not listed? Get in touch:

Contact usKey Manufacturing Capabilities

-

Passive/active high-precision alignment

-

High-precision bonding accuracy

-

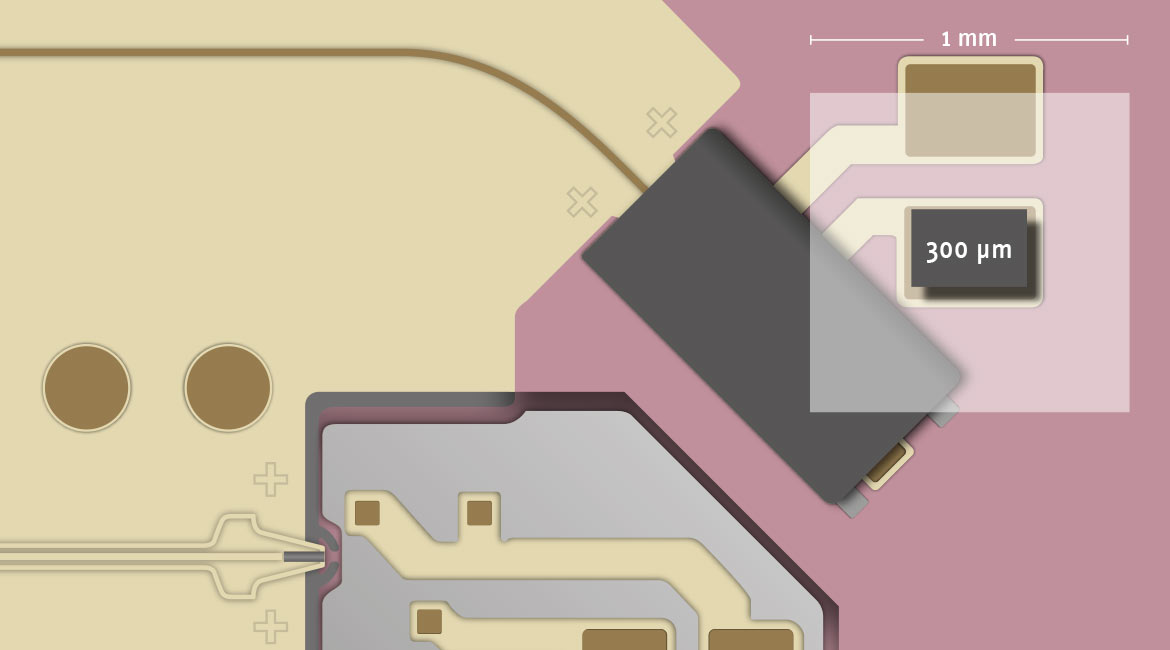

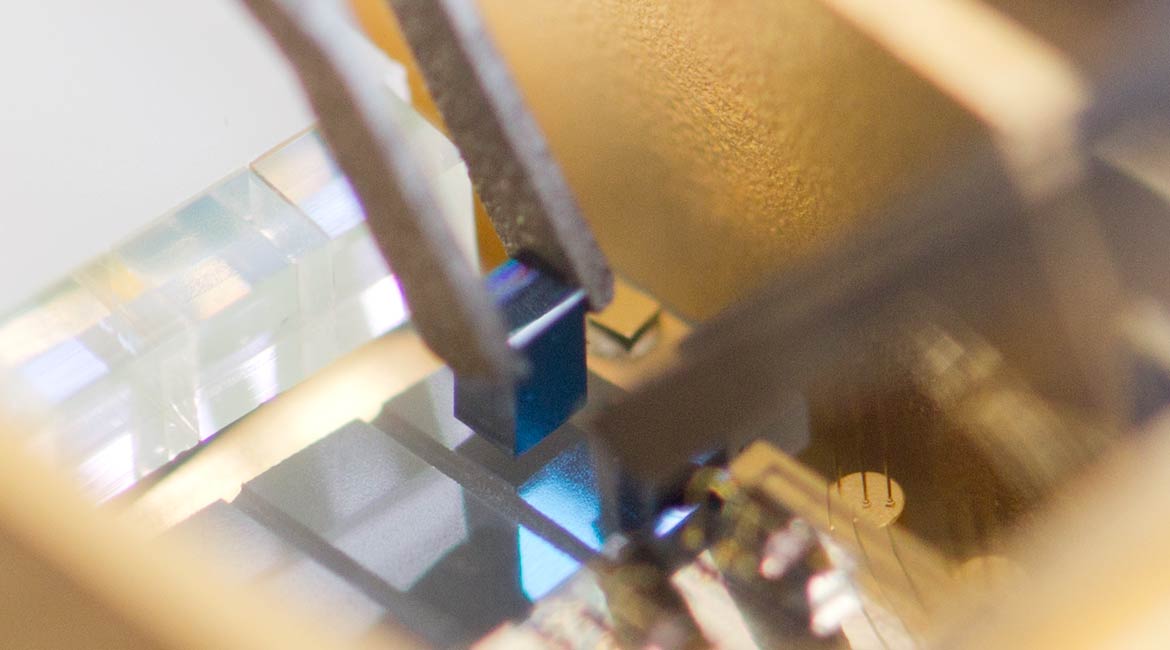

Flip-chip align-&-attach

-

Chip-on-Submount (CoS)

-

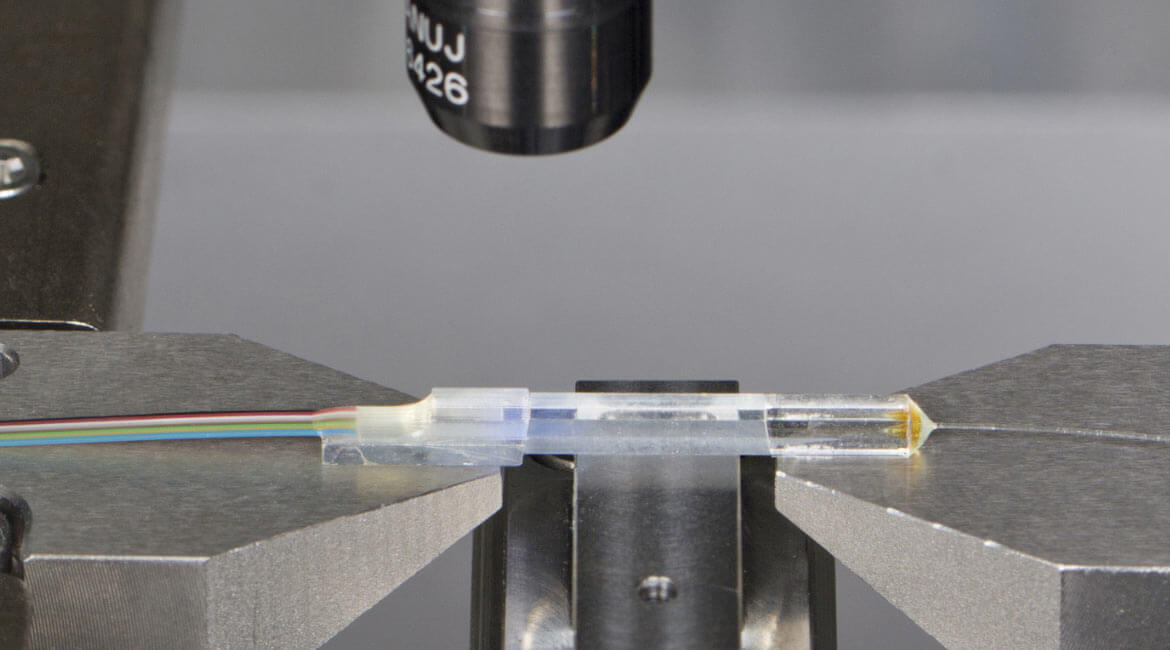

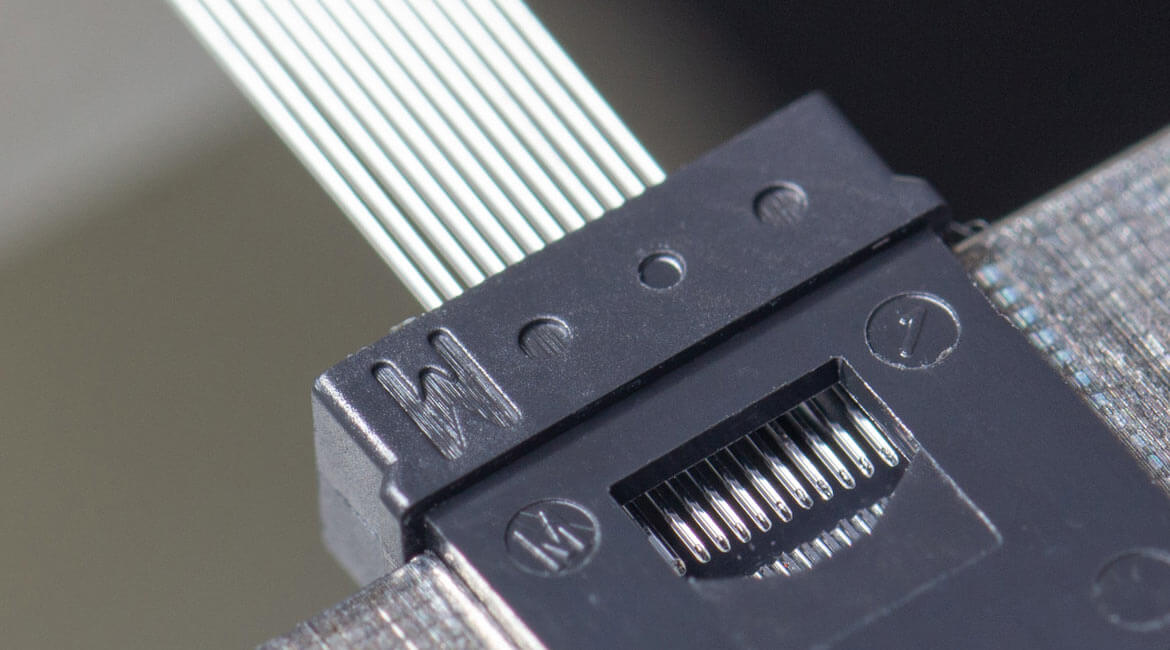

Hybrid integration, fiber alignment & pigtailing

-

Optical element assembly into packages

-

Simultaneous alignment of two optical elements

High-precision positioning systems

In-package align-&-attach

Custom test probe heads

Laser to waveguide using flip-chip assembly

-

Pick-&-place & handling of sub-systems

-

Die sorting and component tracking

-

Welding, soldering, or (UV) epoxy bonding

-

Adjustable bond force

-

Process parameter sequencing & tracking

-

Acquisition of operating parameters into a database

-

OCR for serial number tracking and component traceability

Simultaneous alignment of two optical elements

Fiber array connector assembly

Complex micro-optical assembly

Vacuum pick-up tools

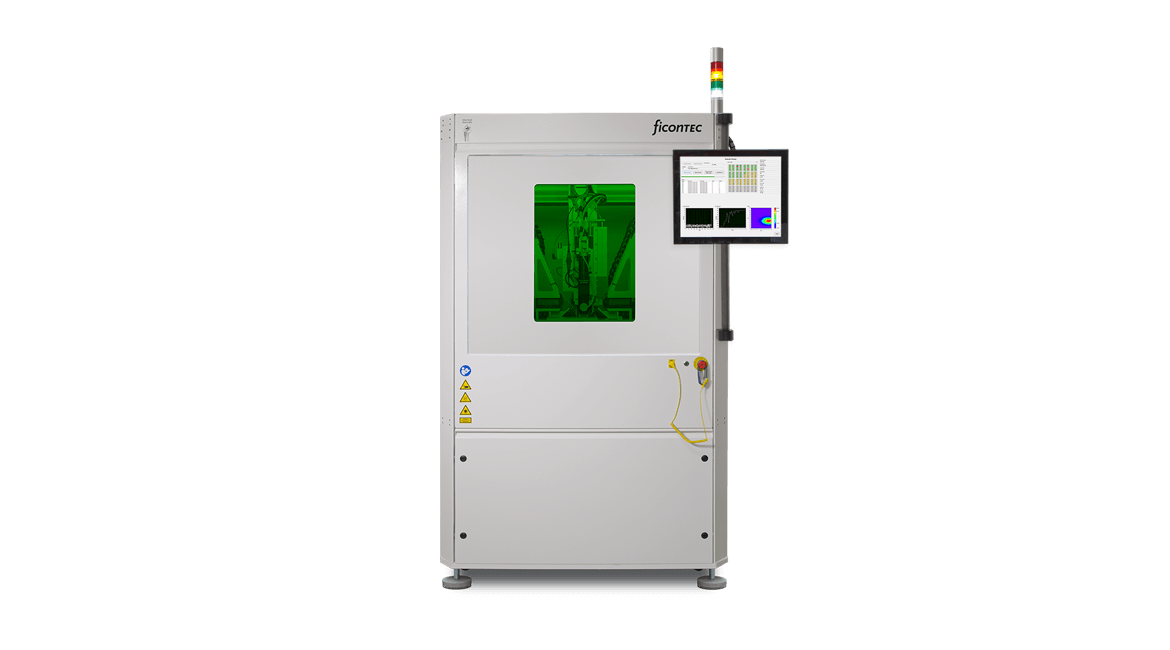

Relevant machine types:

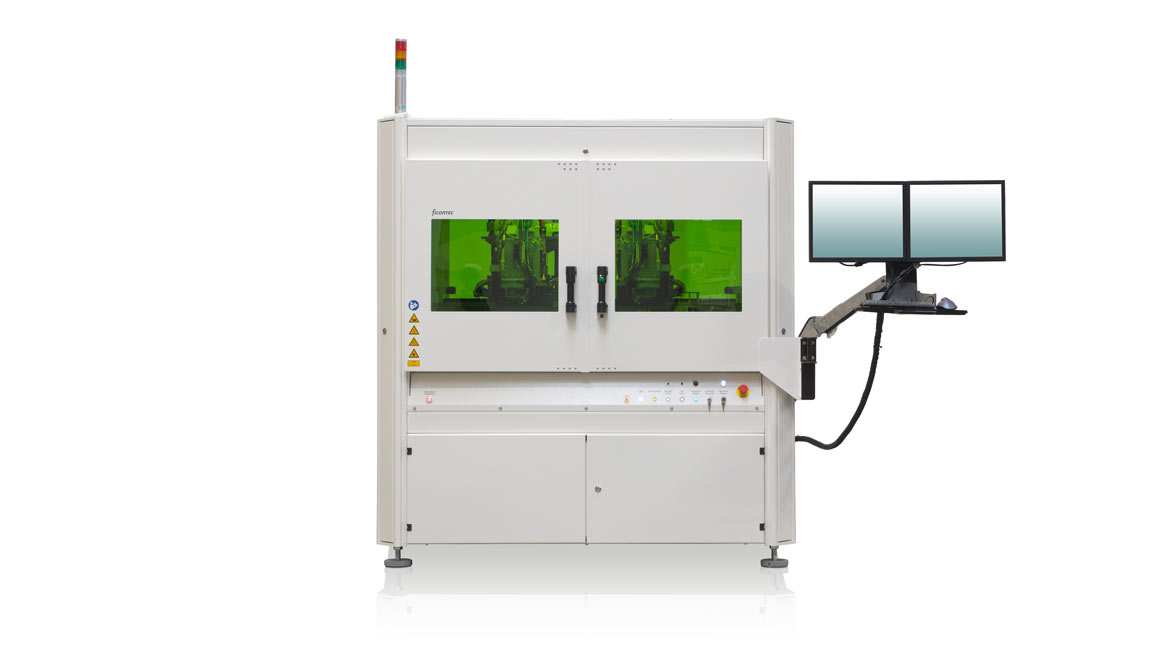

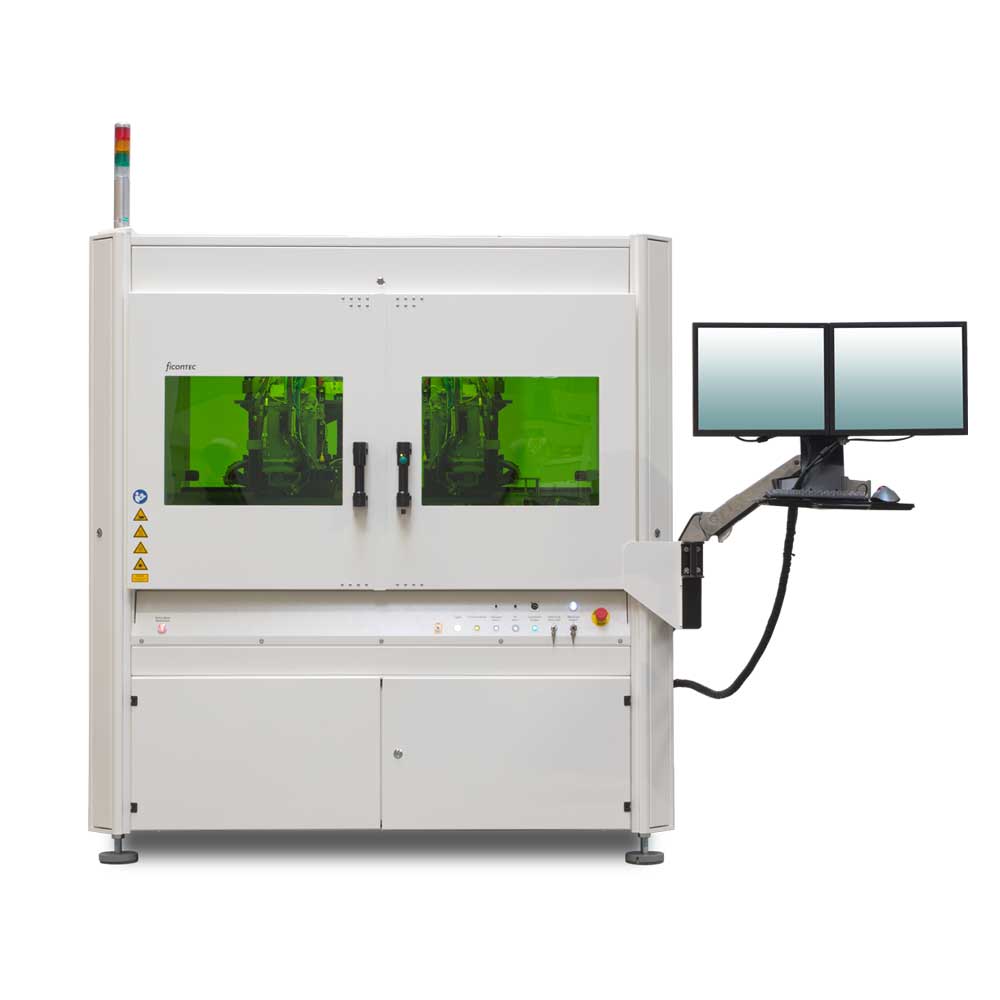

ASSEMBLYLINE, CUSTOMLINE

Die-level photonic device assembly