Mechatronics For Photonics Assembly & Test

Flexible, highly modular and fully-integrated

mechatronic technology controlled by a powerful software tool

Today, photonic devices for high-tech applications are becoming increasingly complex. Ever larger numbers of optical elements with diverse photonic properties must be integrated into ever smaller packages.

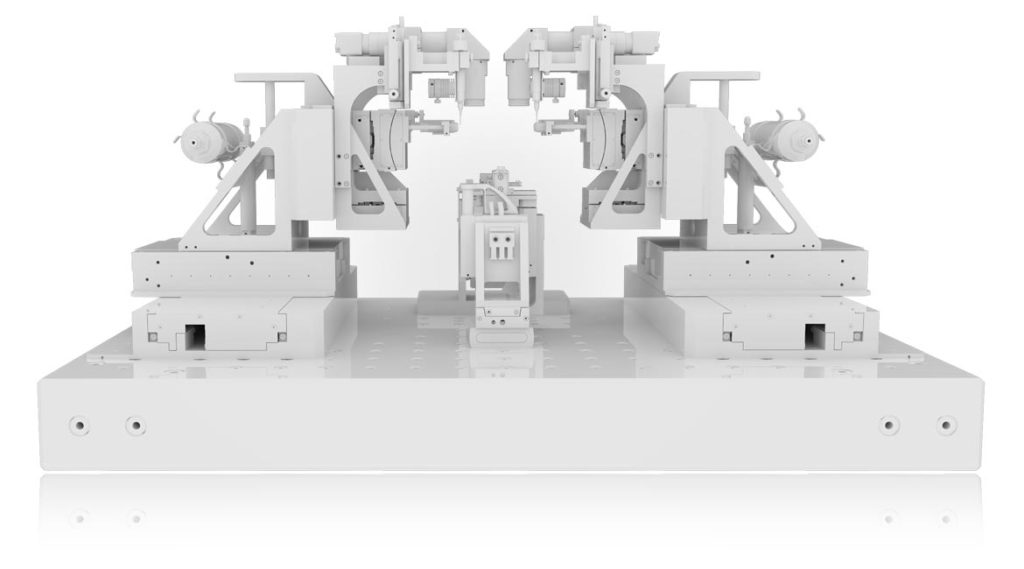

ficonTEC production systems fulfill the definition of state-of-the art mechatronic systems, encompassing fully integrated advanced mechanical motion/positioning elements, electro-optical instrumentation, and all orchestrated by a powerful software interface.

With the accumulated experience that comes with an extensive global installation base of over 1000 machines, continued development has led to several well-established, highly modular and fully integration-capable product lines. The result is ever higher levels of performance and reproducibility, diminishing unscheduled downtime via optional predictive maintenance, and thus higher yield and lower cost/part for the very devices our machines are designed to assemble.

These continuous developments also enable us stay ahead of the rapidly changing customer manufacturing needs in photonic component assembly.

Motion Control For Accurate And Repeatable Positioning

High-end stages combined with state-of-the-art real-time motion controllers guarantee easy and accurate positioning

The best motion stages available are complemented with proprietary technology to combine precision with industrial-grade robustness

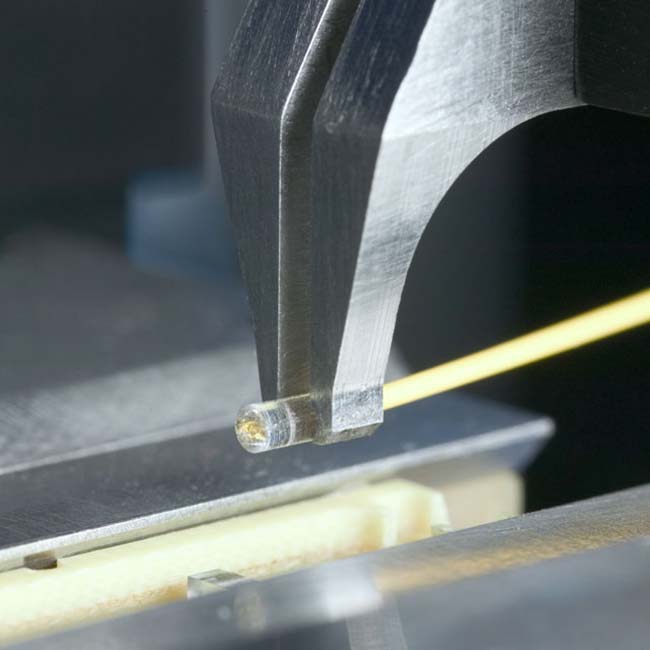

Accurate, repeatable and reliable positioning of tiny components over millions of cycles is one of the main considerations in the design of our machines. Conventional stacks of linear translation and rotational (goniometers) stages, hexapod-like 6-DOF (degrees of freedom) devices, long-travel gantries, as well as SCARA and anthropomorphic robots are routinely integrated in our machines. State-of-the-art real-time controllers ensure fast positioning interpolation for multi-axis systems with advanced functionalities such as pivot-point-based motion space and fast active alignment.

These motion systems form an integral core element of our automated assembly machines, providing high-precision positioning (nm-resolution coupled with 50 nm and sub-arcsecond accuracy) as well as in-line process pick-&-place capability.

Last but not least, all hardware functions are controlled by ficonTEC’s flexible, modular and easy-to-use process programming software, PROCESS CONTROL MASTER.

Need clarification on motion system configurations and capabilities?

Contact us

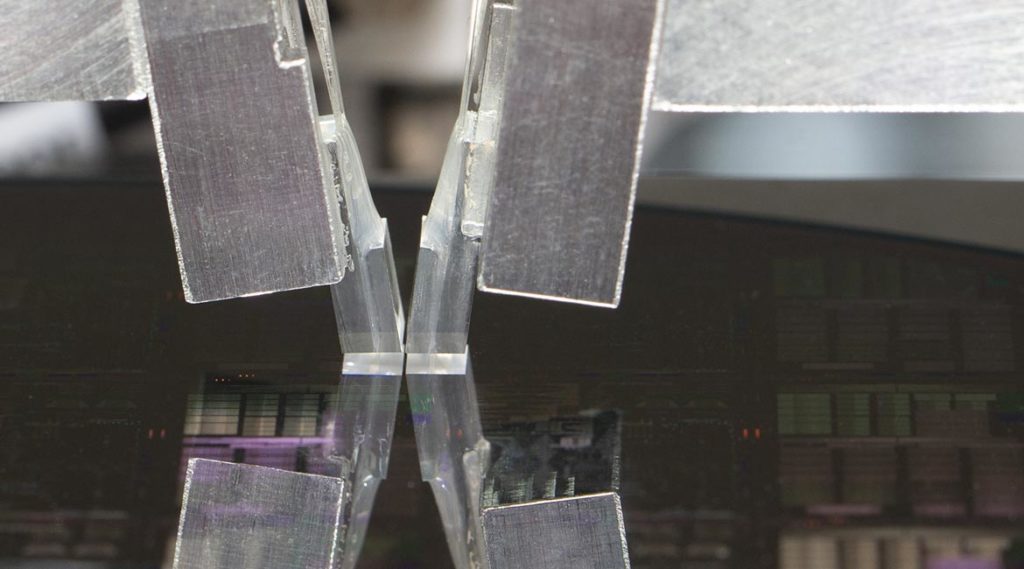

Dual fiber array positioning over waveguides

Bonding For High Yield And High Performance

Multiple bonding approaches are available to ensure reliable performance and long component lifetime

ficonTEC provides several well-established component bonding

technologies for many photonics micro-assembly tasks

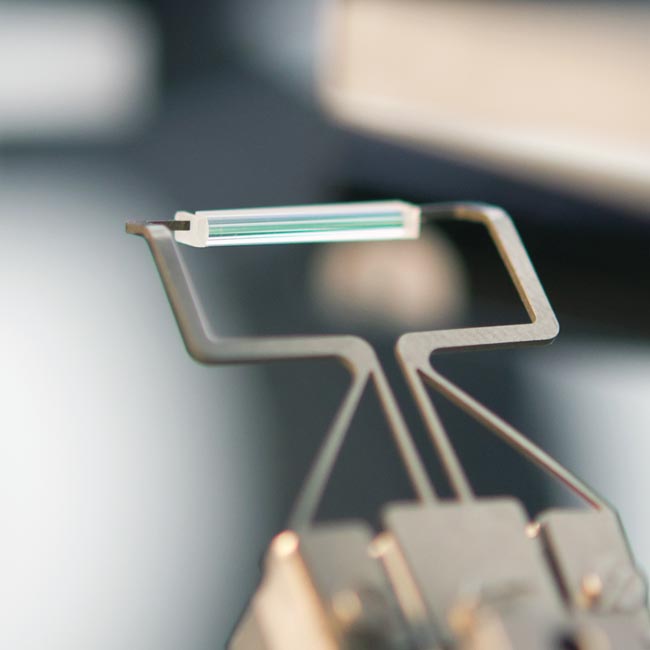

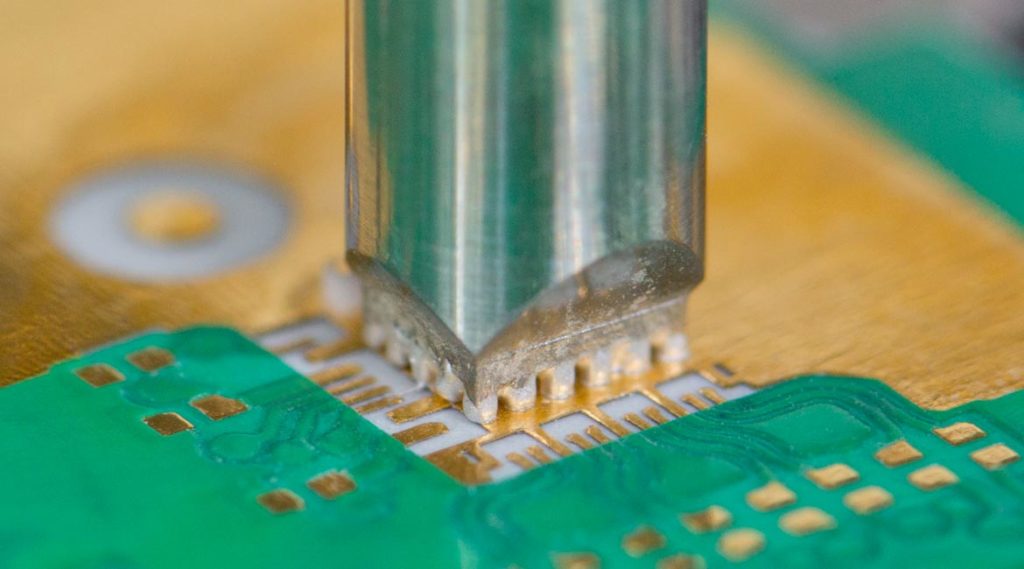

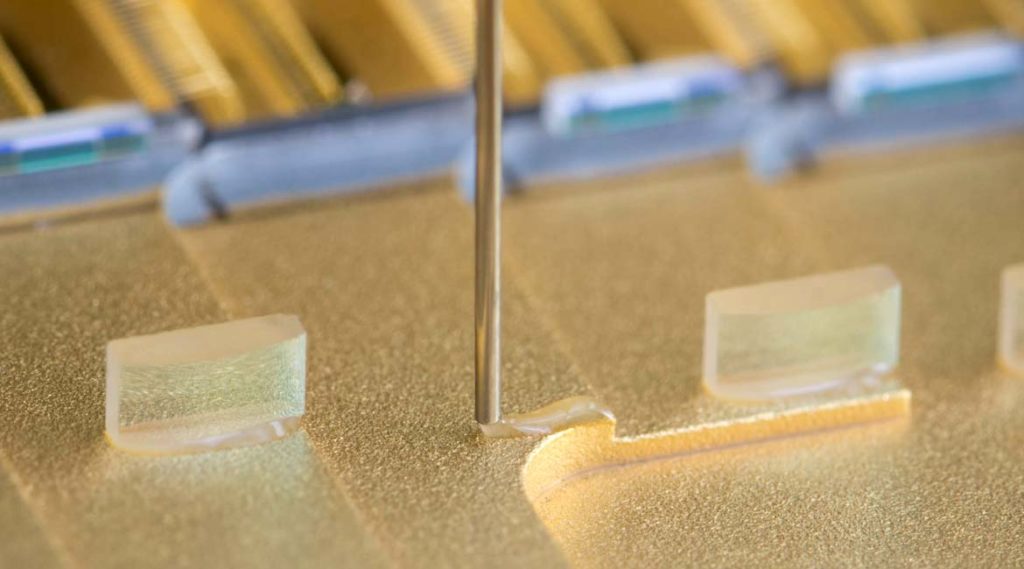

The various bonding approaches – UV and/or thermally cured epoxy, brazing, soldering and reflow processes as well as laser soldering and laser welding – are extremely critical procedures during micro-assembly. Typical applications include laser diode chip and laser bar bonding, as well as the bonding of photodiodes, micro-optical elements and lenses, optical fibers, LEDs, etc. onto a substrate, a submount, or even onto a full photonics wafer.

An automated approach for the selected type of bonding must provide absolute control over the process, and must thus accomplish several tasks and goals:

- accurate dispensing of different viscosity adhesives for epoxy bonding

- accurate component re-positioning following dispensing, regardless of the type used

- properly distributed/timed UV flashing or thermal curing

- active shrinkage compensation for UV-expoxies

- accurate guiding and focusing of laser beams for laser welding

- controlled thermal cycles / thermal distribution for soldering and laser soldering

- also be capable of opto-electronic flip-chip assembly

For epoxy-based bonding approaches, we work closely with manufacturers and with customers to make sure the correct type is chosen for the intended application. Laser soldering options have recently improved thanks to a through-silicon ‘align-&-attach’ process recently developed by ficonTEC R&D.

Laser welding

Soldering (also laser-based)

(UV) epoxy bonding

Die And Wafer-level Electro-optical Testing

Fully automated design validation and device verification, for singulated chips through to wafer-level devices

Design validation and device verification will in future mean combined electro-optical probing of singulated and on-wafer devices

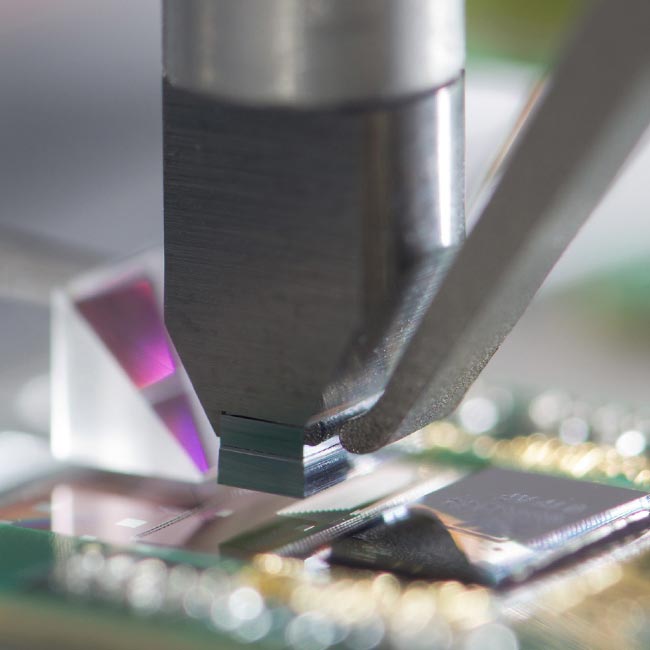

Many diverse forms of testing at ‘single die’ or at ‘packaged device’ level has been a frequent element of ficonTEC’s production systems – this is typically an unavoidable step within an (extended) assembly process. Now, as volumes in photonics manufacturing increase, highly automated and highly capable testing machines are gaining their own space.

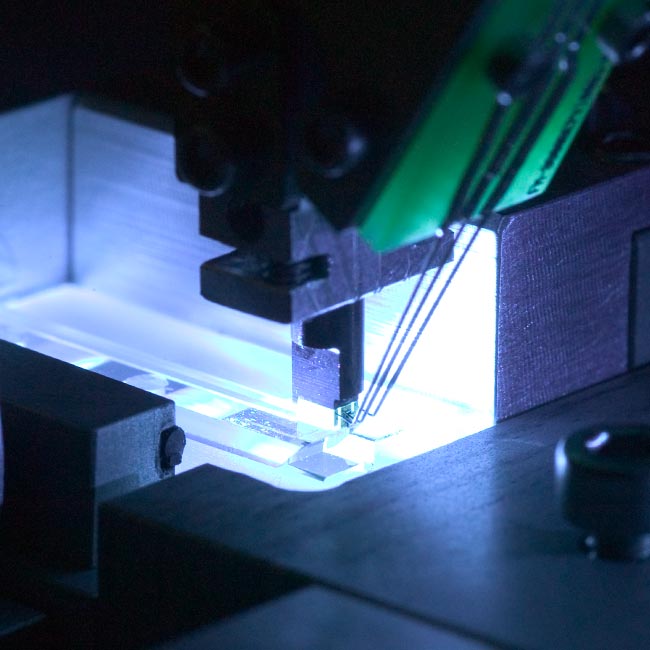

We are also seeing a clear trend toward full wafer-level photonics testing. In the semiconductor world, wafer-level testing with probe cards holding several thousand pins are common, with typical contact pads of 80 x 80 µm². Optical probing, however, requires much higher positional accuracies – in the submicron range – and utilizing either vertically accessible grating couplers or edge coupling at the wafer.

As both electrical and optical probing is needed to test photonic devices, ficonTEC is already developing combined electro-optical approaches. As the number of optical channels for simultaneous testing increases, more demands will be put on high-channel-count modular instrumentation, including tunable laser sources, multi-channel power meters, optical switches, etc.

Testing protocols and automated testing sequences can again benefit from our configurable PROCESS CONTROL MASTER software, with direct interfacing of process tracking data to an SQL database, thus providing the user with access to statistical analysis of the data, for example as a tool for improving production yield.