Software Control

Controlled by our flexible process control software, our machines become vastly more than just the sum of their parts

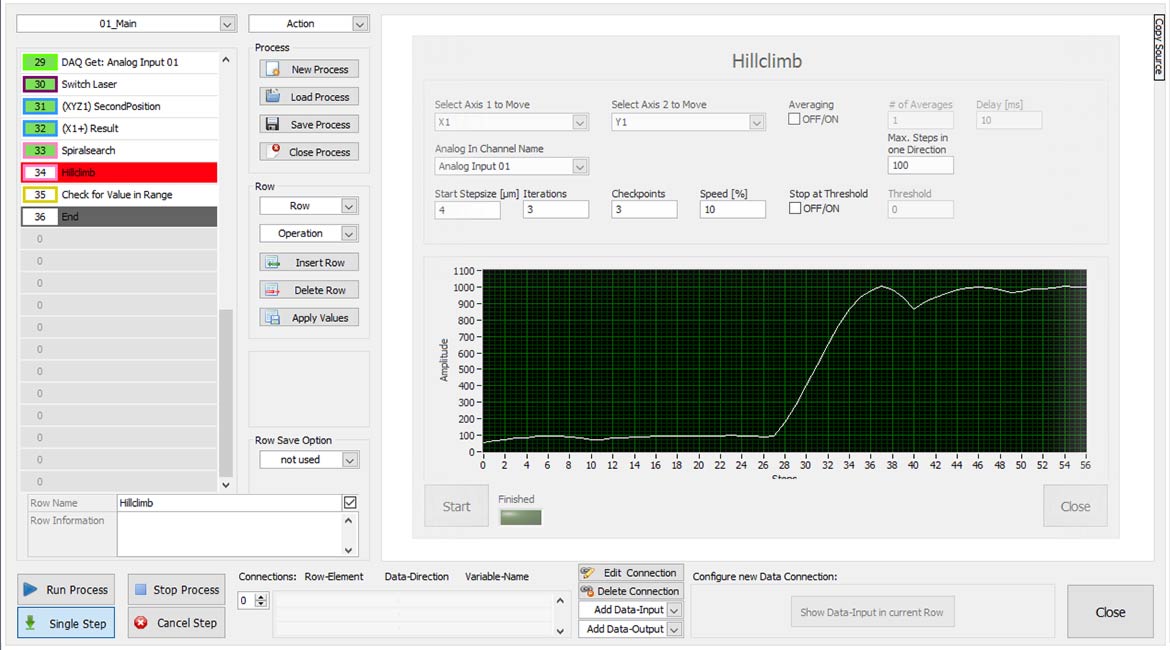

Probably our most important product feature, PROCESS CONTROL MASTER (PCM) is our user-friendly and process-oriented software control interface that is shipped with all turn-key, ready-to-use machines and multi-machine configurations. Flexible process control and scalable options enable customized assembly & test solutions suitable for early device development, for new product introduction, and for high-volume manufacturing (HVM) – no knowledge of programming is needed.

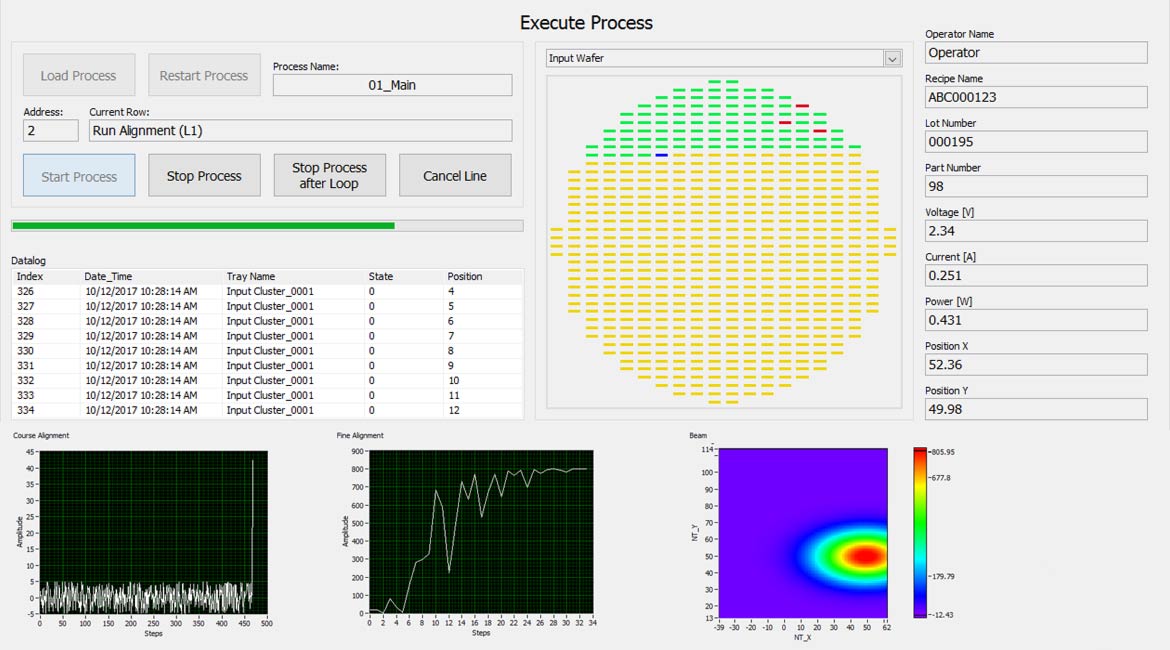

PCM features an intuitive machine/process interface that includes all referencing, positioning, handling, system control & management as well as machine vision routines required to reliably and repeatably drive all available processes and hardware. It also comes already fully enabled for automated electro-optical test and characterization tasks, including routine tests such as optical power insertion loss, spectral measurements, electrical/optical bandwidth and temperature dependence measurements. Control of more complex modular instrumentation such as tunable laser sources, multi-channel power meters, optical switches, etc. is also included.

PCM drives not only our single stand-alone systems, but is also already tried-&-tested for multiple (in-line) machine installations employed in HVM environments. For traceability requirements, testing protocols and automated testing sequences gain benefit from direct interfacing to an SQL database, also providing the user with access to statistical analysis of the data. Also, in order to cater to the full spectrum of operational installations, PCM enables as much or as little operator intervention as required, even entirely autonomous operation, via optional Service add-ons. For example, our Remote Services makes use of a Remote Control Server (RCS) to provide remote monitoring and control of single systems and lines – and additionally also enables syncing of multiple installations.

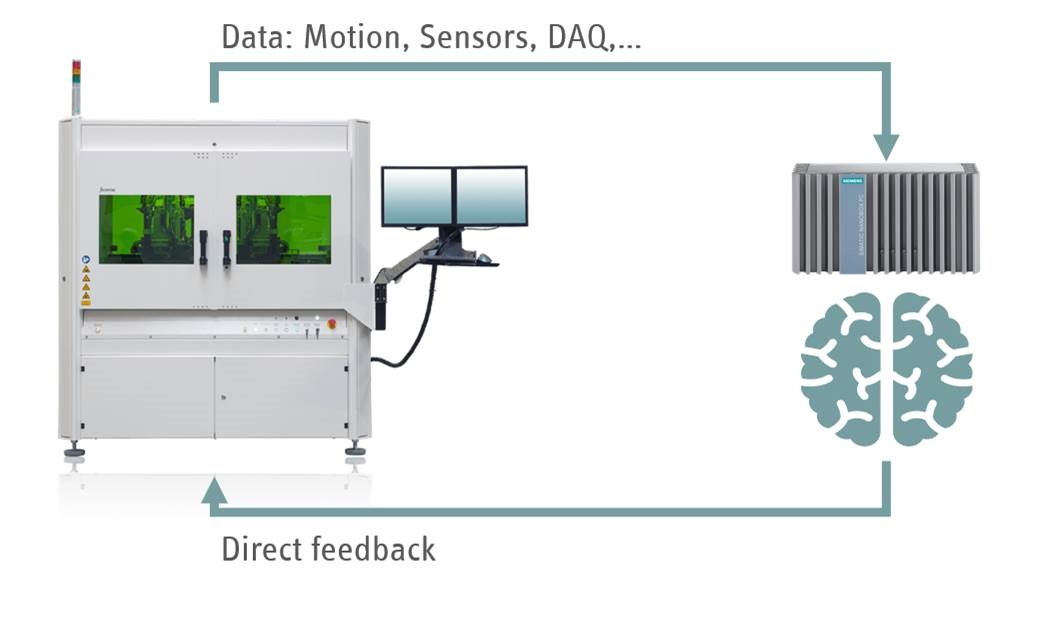

For remote installations requiring more autonomy and minimal unscheduled downtime, overall system reliability and performance can be enhanced through hardware analytics. Here, an AI-driven Machine Learning (AI/ML) layer – ficonEDGE, see below – is integrated into PCM to monitor and analyze all of the operational performance data that is automatically logged by the system, thus realizing the full potential of this data for optimization purposes. The predictive analytics algorithms employed greatly simplify the establishment of process and machine metrics, provide timely scheduling of maintenance, and enable the development of low-latency adaptive maintenance and self-optimization capability – in particular vital for installations operating at the Edge.

Last but not least, PCM’s open access architecture enables integration of commercial or individually designed drivers for additional or bespoke instrumentation and/or specific process management.

Key Features

-

Expansive, powerful library of assembly & test functions

-

Process editor for fully configurable process sequencing

-

Pre-loaded with advanced machine vision routines & algorithms

-

Recipe-based management of process steps & parameters

-

Software drivers for direct interfacing to a wide range of instrumentation

-

Open access architecture for custom code & drivers

-

Component tracking from input/output trays and wafers

-

Flexible data import and export for process/yield monitoring

-

SQL database storage of process parameters and component data

-

Development tools: de-bug, position/jog panel, camera view, etc.

-

Interface can be configured to show real-time operational data

-

For stand-alone systems and multiple in-line machine configurations

-

‘Crash protection’ boundaries for motion system

-

Logging of operation-critical process steps & performance data

-

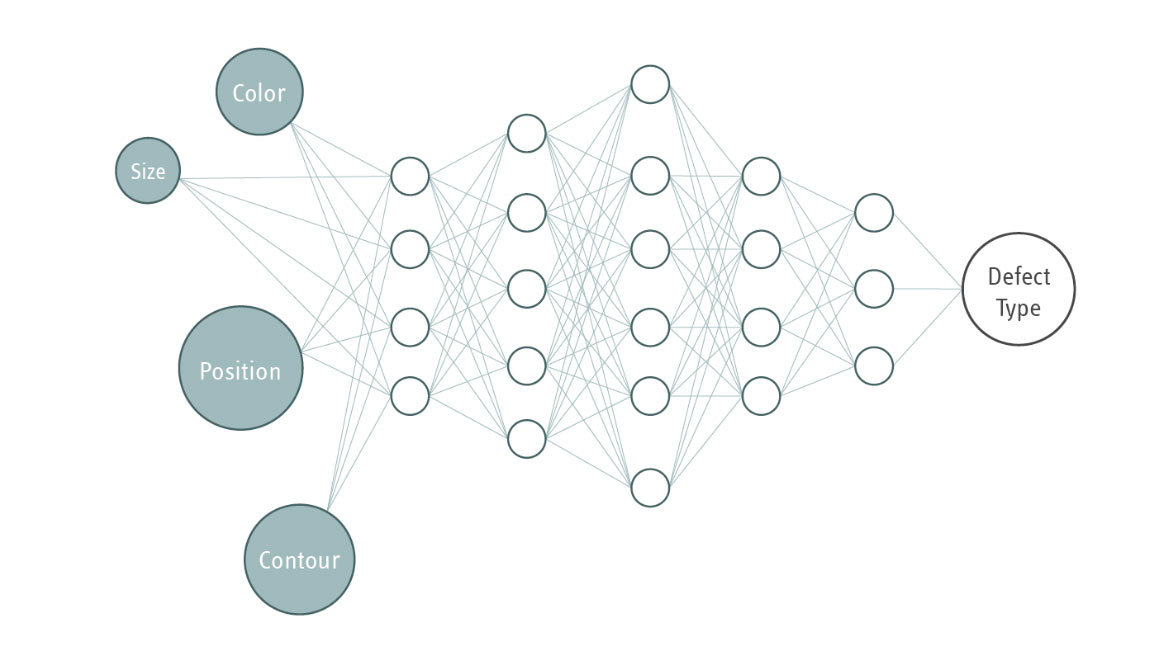

Deep Learning tools for optical inspection

-

Remote service and software upgrades via internet

-

System-wide implementation across all machines, for consistent ‘look & feel’

-

ficonEDGE – AI-driven Machine Learning for performance analytics

Process optimization

Specific manufacturing steps can be so designed or later automatically trimmed to optimize the process sequence and shorten cycle time

As volume requirements increase, ficonTEC can help customers with their process optimization at all stages of development and realization. By working closely with the customer and understanding their needs properly, we can lever our own 20+ years of extensive active development to assist in the production process design – including those aspects relating to software control. We assist in evaluating existing processes and methods, optimizing and developing innovative processes right through to their implementation, resulting in optimization of the assembly processes and thus achieving maximum production efficiency. This is of particular importance in translating manual assembly and testing protocols during the migration from prototyping / low volume to full mass production.

The PCM software platform provides powerful and adaptable process tuning and sequencing that can be further optimized, for example at a later date, by leveraging the statistical data stored in the SQL database.

Yield, cycle time, device performance and cost per part can all be optimized within the available parameter space allowed by the production process, within a single cell installation or across entire production lines comprising multiple in-line machines. Finally, for high-volume demands employing multiple identical lines, a Revision Control Server (RCS) can be implemented to synchronize process parameters across all lines, thus enabling maximum repeatability and consistency of performance and yield. The RCS can be managed locally or remotely, with obvious benefits for global players within the photonics market.

By starting to optimize each step right from the design phase –introducing innovative processes, utilizing high levels of advanced automation for even the most demanding assembly tasks, and holding it all together with industry-tested software control – ficonTEC provides a proven and dependable route to high-volume manufacture.

PCM-SoftwareficonEDGE

ficonTEC’s new EDGE computing platform

ficonEDGE empowers our customers to collect and leverage data from production, thereby opening the door to data-driven optimization of production KPIs using cutting-edge machine learning. Use cases include:

- Self-adaptive production: By integrating model outputs directly into the machine process, a closed loop is formed between machine and edge platform. No human interaction is required, thereby saving resources for where they are really needed.

- Yield & process control by automated analysis & alerting: Allowing your local production team to review & analyze data conveniently with a well documented dashboard solution. Alerts can be easily distributed via common messenger systems and even configured for direct interaction with the machine.

- Predictive maintenance: Monitor the status of critical machine components in real time, identify potential upcoming hardware issues and efficiently manage – and thus minimize – any necessary service downtime. Read more…

Learn how our use cases can improve your production.

Contact us Learn More Read post