October 2023

ficonEDGE – Enabling self-help in the Machine

What is ficonEDGE?

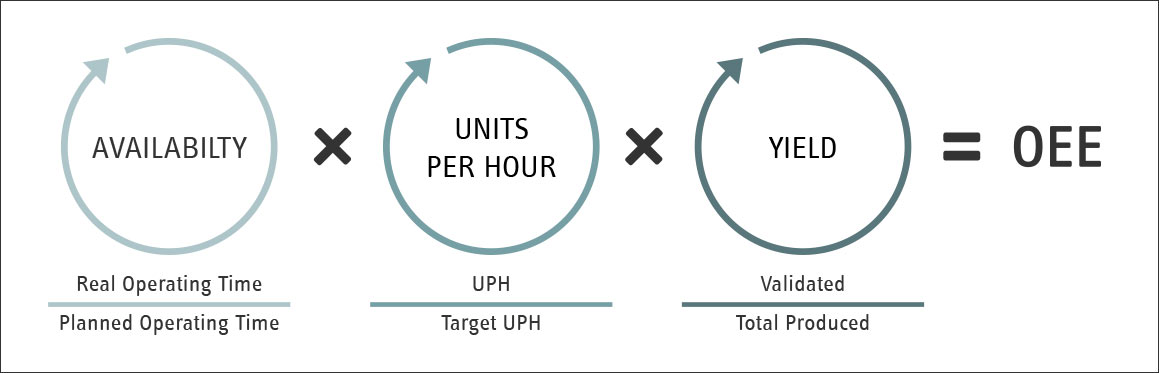

ficonEDGE is ficonTEC’s new machine learning (ML)-driven EDGE computing platform. By offering advanced use cases to customers – all via a custom add-on hardware and software layer – ficonEDGE automatically maintains production yield while the system operator stays ahead of potential upcoming issues. The result is maximized overall equipment effectiveness (OEE) and optimized total cost of ownership (TCO).

ficonEDGE and the machine

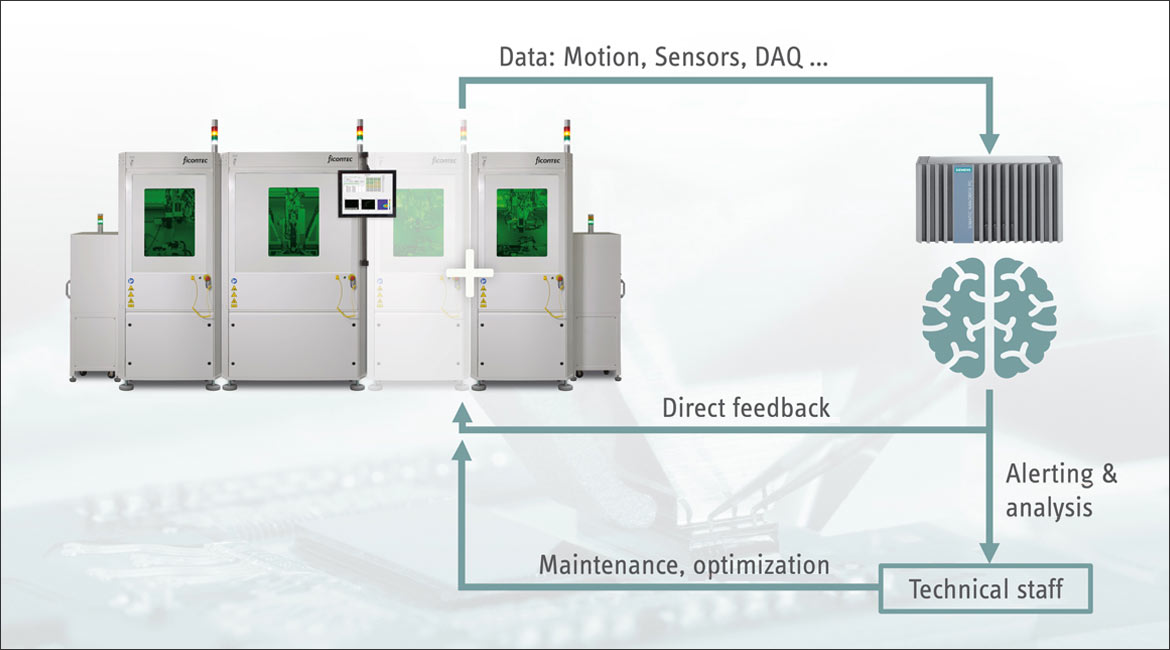

ficonEDGE uses the infrastructure provided by the Siemens Industrial Edge eco-system – an industry-proven and highly secure edge computing platform and central management system. In short, this provides a backbone architecture for machine builders such as ficonTEC that facilitates ficonEDGE’s effective operation.

ficonTEC has worked together with major globally operating device manufacturers and R&D partners over the last few years to create an industry-ready package that is primarily targeted at mid to high-volume industrial photonics manufacturers, but that also adds value in lower volume cases. In real terms, ficonEDGE comprises a flexible hardware and software layer that is available as an add-on for new and existing production

ficonEDGE and the machine

What is the problem that this solves?

Photonic device manufacturing is a rapidly evolving sector, with multiple factors influencing OEE and therefore impacting TCO:

- Rapid technology development means short model lifetimes and frequent reconfiguration of production systems.

- Proprietary, non-standards-based packaging approaches constrain the viability of model transfer between product iterations and successive devices.

- Global operations face multiple geography-related issues, primarily centered around real-time production monitoring and availability of qualified personnel to address issues.

- Unexpected, a.k.a. unscheduled downtime kills yield targets and reduces profit margins.

Although well known to industry at large, these factors are an increasingly relevant issue for photonic device manufacturing as the sector is rapidly scaling up. The workaround to any volume manufacturing bottlenecks is of course ‘automation’ – not just within the process steps themselves, but also of the machine performance.

ficonEDGE leverages production data sourced from typical data logging as well as from additional information gained by supplemental sensor and DAQ data streams. Application-conform ML-based analysis tools can recognize uncharacteristic behavior and directly adapt machine parameters to changing conditions.

We can now directly address the points raised above:

- Production models rapidly ‘home in’ on and maintain optimized process parameters. Easy configuration & fully automatic training of new models is enabled without prior data science knowledge.

- The self-adaptive capability reduces the dependency on previous models.

- Process analysis via custom dashboards. Automatic alerting enables further, location-independent pre-emptive process and yield control.

- Potential hardware failures and risks for yield degradation are automatically flagged. Unscheduled downtime is reduced.

Overall equipment effectiveness

Is your OEE paramount?

ficonEDGE empowers customers to collect and leverage data from production, thereby opening the door to data-driven optimization of production KPIs using cutting-edge machine learning. ficonEDGE has been developed, augmented and enhanced in real-world industrial photonic device manufacturing settings over several years.

If you are looking to purchase, or indeed already implement multiple ficonTEC systems either for batch manufacturing, or in an in-line, medium to high-volume manufacturing (HVM) environment, feel free to engage us in a discussion of the potential advantages of ficonEDGE for your particular application.