LIV – (High-power) Laser Diode Testing

Testing and characterizing the light-generating devices

at the very heart of photonics technology

An important aspect of the development and manufacture of laser diodes is the so-called laser diode characterization, or laser IV curve. By applying increasing current to the laser diode so it that emits light, the optical output is measured together with the voltage drop across the diode element. The resulting LIV curve reveals important clues about the quality of manufacture and the performance of the laser diode, enabling a pass/fail decision to be met.

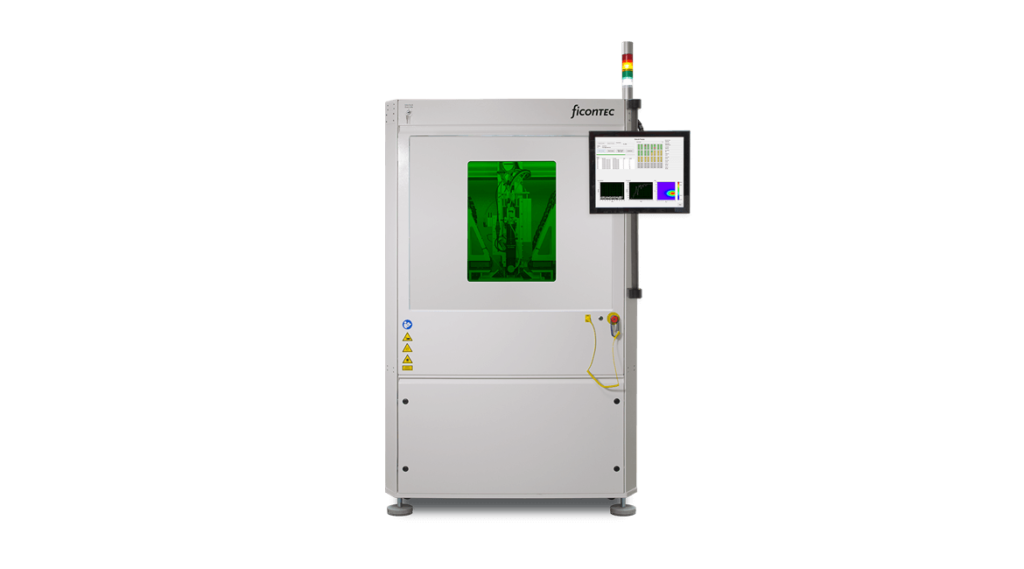

To test if all functional components are meeting specifications, ficonTEC provides automated testing systems. The characteristic laser parameters are measured by running an LIV or, instead, a DC sweep. Parallel to the optical power, the optical output spectrum and near and far-field optical characteristics (amongst others) can also be measured.

The latest integrated designs, which incorporate both electronic and photonic devices on a hybrid device, provide benefit in terms of functionality, miniaturization, high-volume manufacture and cost/part. However, these high-volume manufactured devices also present a number of challenges during device testing, and require ever higher levels of automation as well as highly parallel, mixed-signal electro-optical testing concepts, both on and off-wafer – a goal to which ficonTEC is already working toward.

The accumulated data is written to an SQL Database, providing the user with the necessary statistical analysis and feedback so that e.g. yield can be tracked and improved. The system allows full component tracking and sorting when equipped with a handling system.

Our testing development is moving rapidly – get in touch for the latest news:

Contact usKey Manufacturing Capabilities

-

LIV testing and beam characterization

-

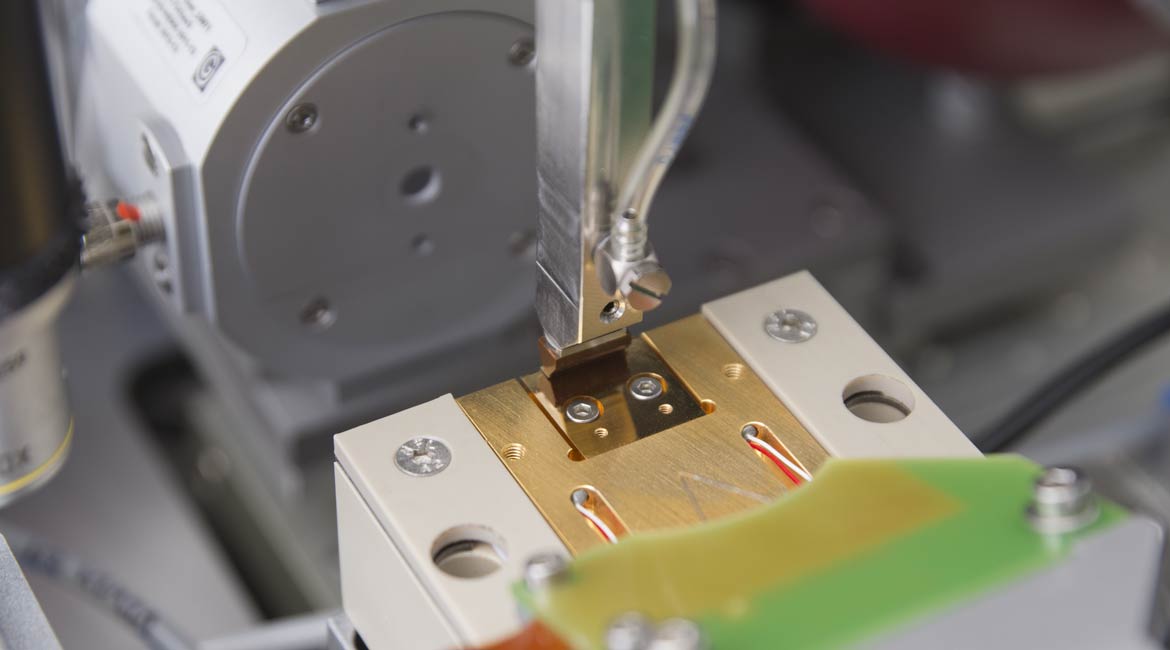

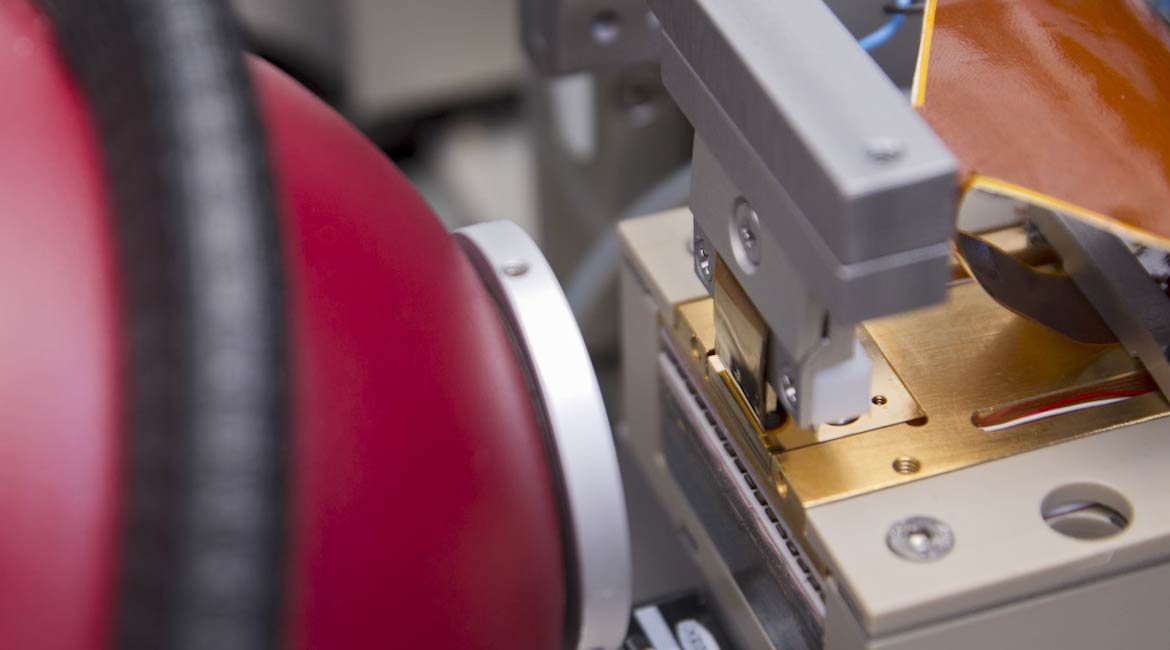

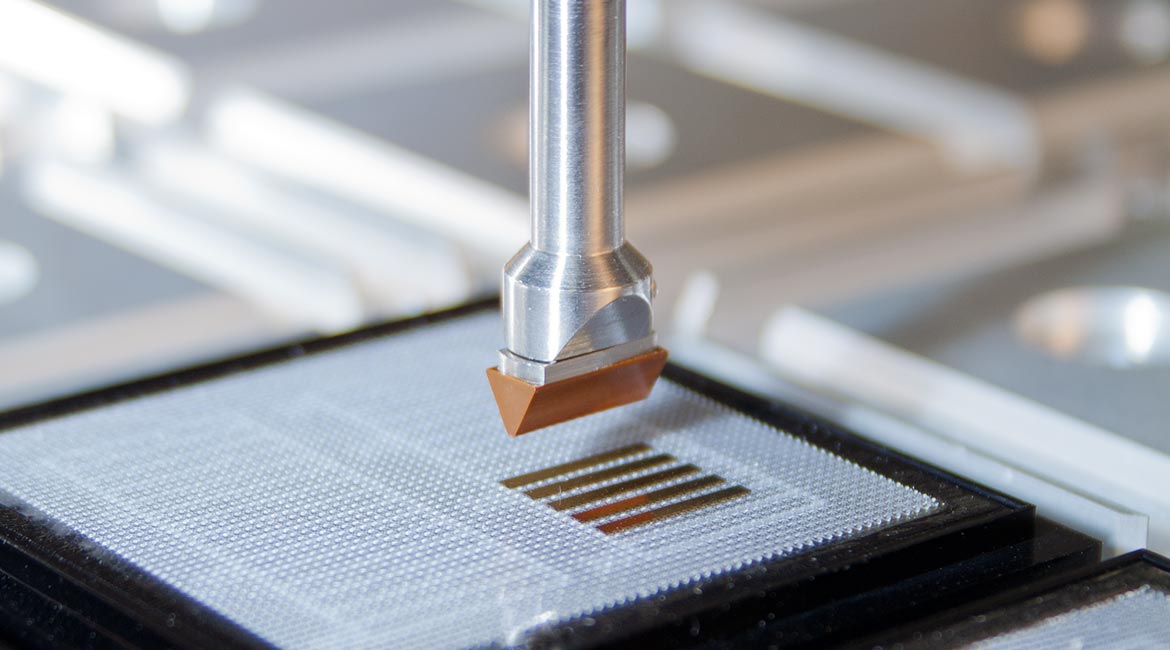

Single emitter chip, or parallel testing of entire bars

-

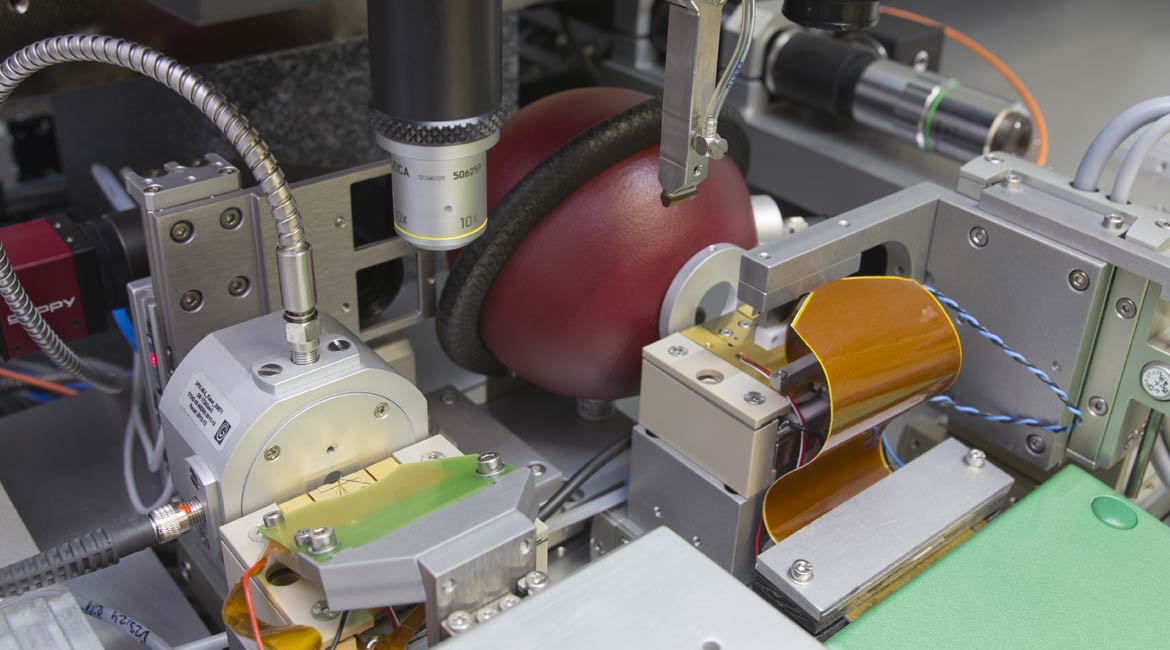

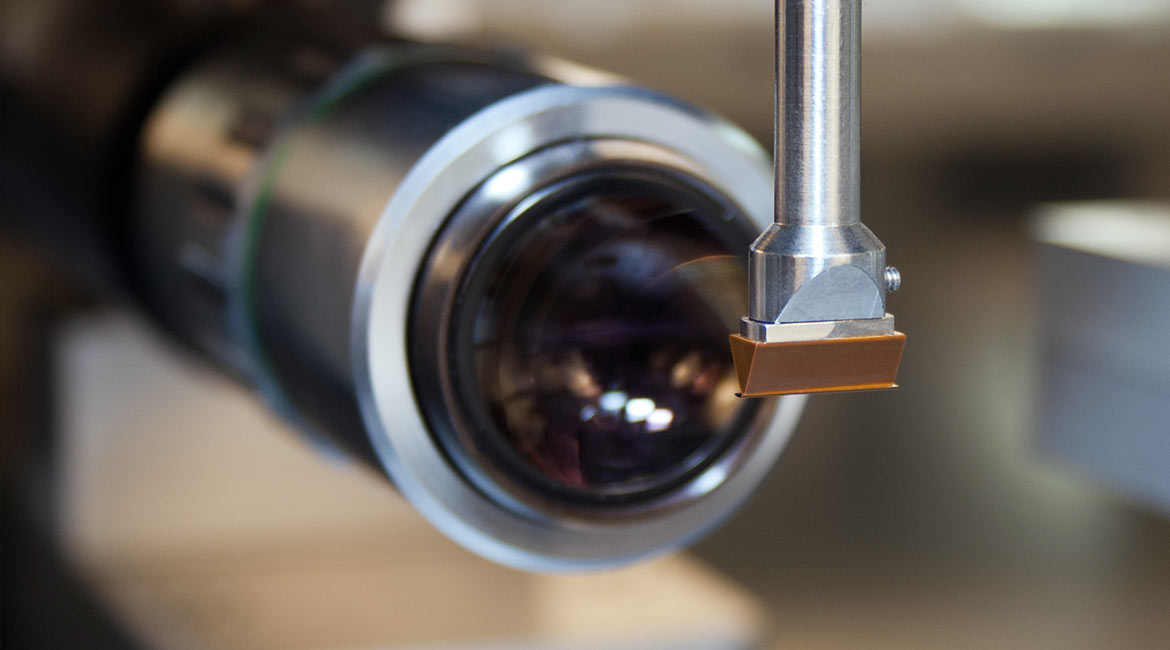

Multiple optical beam parameters can be measured simultaneously

-

All acquired and statistical data written to SQL database files

High-power bar & CoS tester

Measurement of optical beam characteristics

Automatic pick-&-place of laser bars on Gel-Pak

Full bar facet inspection

-

LIV, spectral and far & near-field tests

-

Fully automatic handling of devices

-

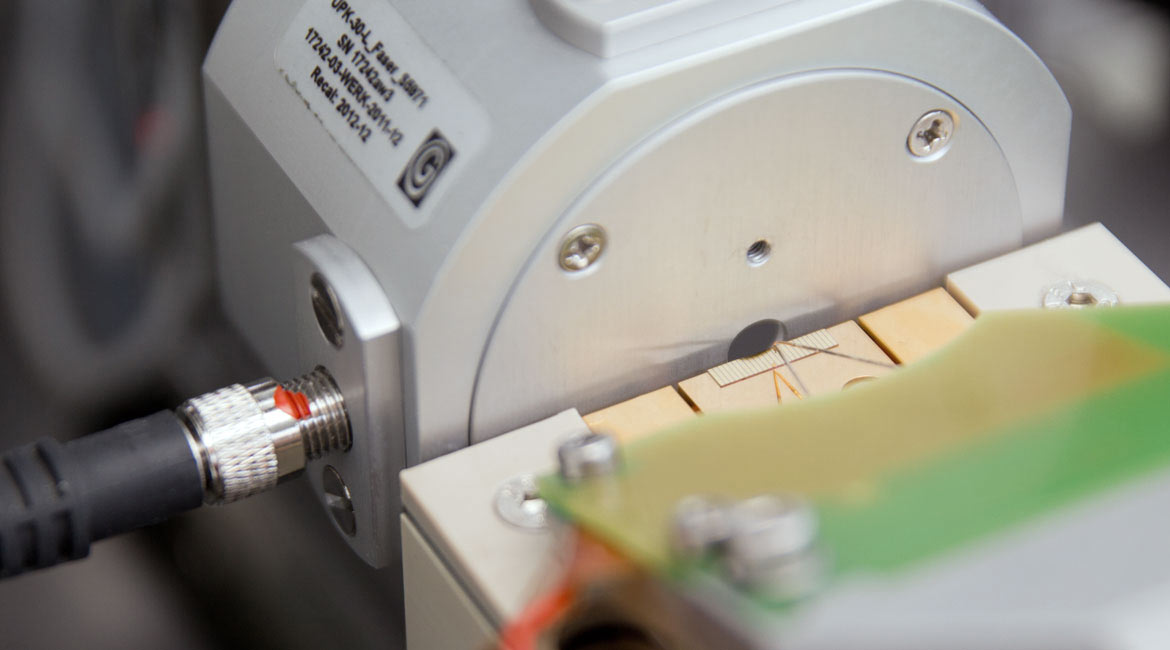

Easy-to-change optical & electrical probe heads

-

Option for component top side and facet inspection

-

Flexible integration of external test instrumentation and test protocols

-

Compatible to SQL and other database systems for data traceability

More information

Relevant machine types:

TESTLINE, WAFER TESTLINE

(some test capability available in ASSEMBLYLINE)

Electro-optic Die-level Tester