Automated Optical Inspection (AOI)

Facet inspection as well as contamination and defect recognition – fast, automated and reliable

No complex assembly process is complete without the ability to inspect and characterize the many different components used. ficonTEC’s fully automated inspection modules for TESTLINE and STACKLINE acquire high-resolution pictures of the surfaces of interest and performs optical inspection based on the user’s criteria. For example, facet inspection of laser diodes, QC for coatings, surface inspection, top/bottom/side-wall inspection of semiconductor chips, and die sorting are just some of the many inspection tasks performed routinely by ficonTEC’s suite of inspection tools

As for all of ficonTEC’s systems, a modular approach permits the inspection platform to equipped with additional features – automatic tray handling and various feeding philosophies, testing capabilities (e.g. LIV), top/bottom chip inspection, and in-situ labelling.

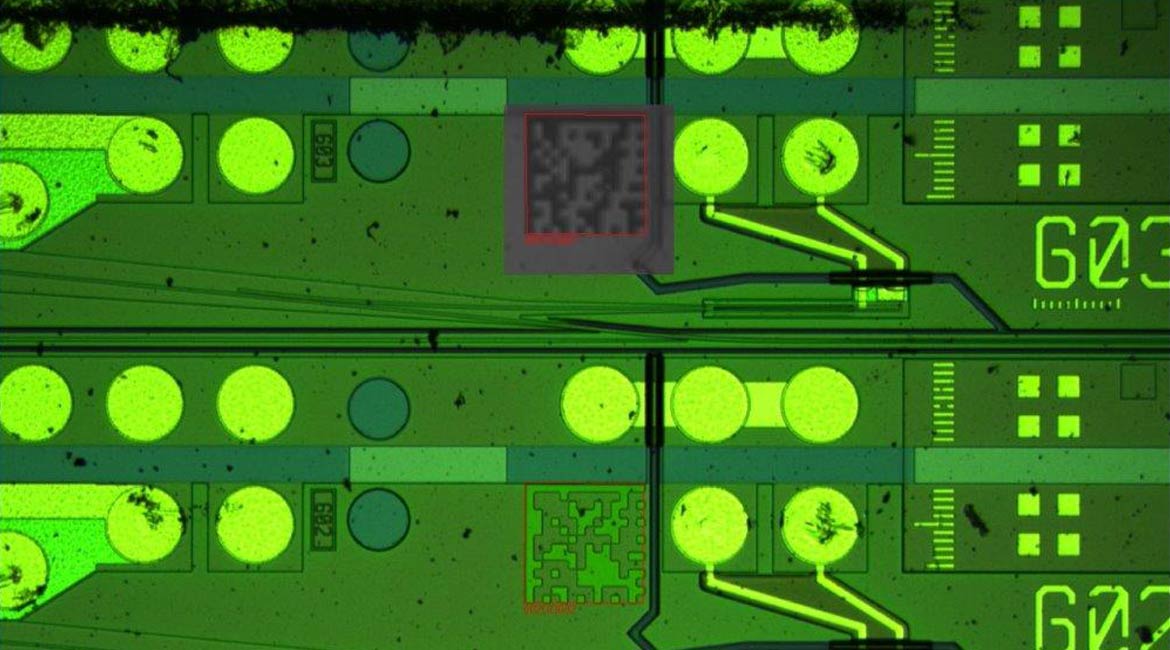

Our defect recognition algorithms now use Deep Learning – see the video.

Watch now

Key Manufacturing Capabilities

-

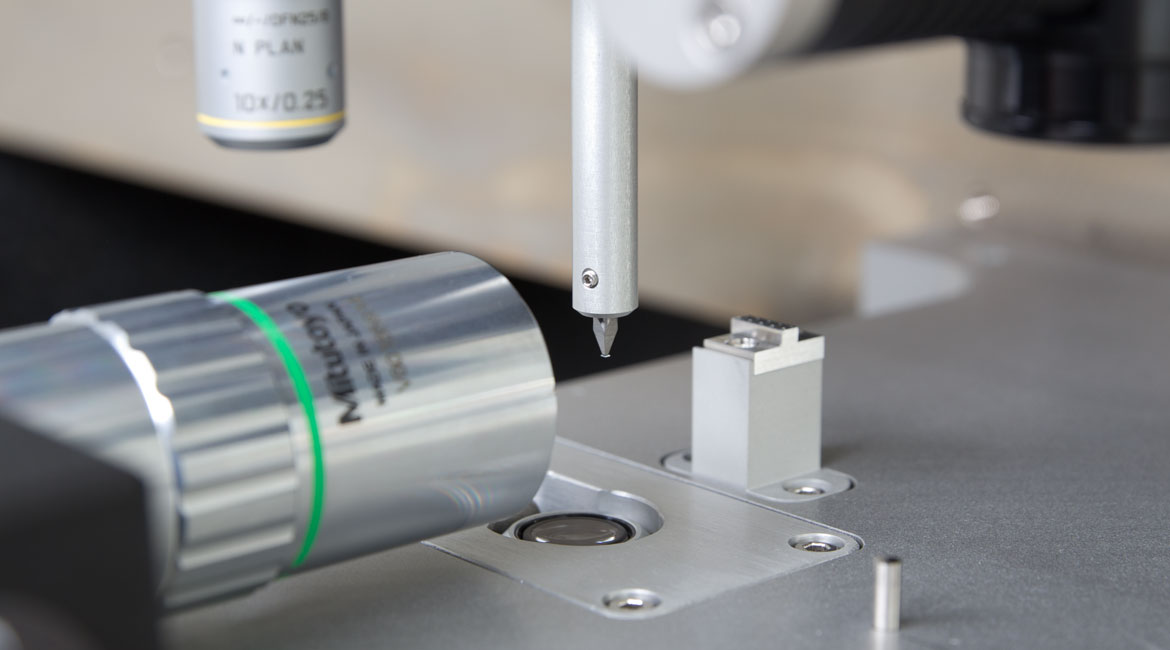

High-magnification imaging system

-

Color camera for individual color channel examination

-

Köhler illumination

-

Chip side wall inspection

-

Die sorting

Facet inspection

Color camera for individual color channel examination

Reading data codes

Locate center of VCSEL

-

Crack recognition

-

Break-out detection

-

Prognosis of crack propagation

-

Particle recognition

-

Dust and fiber recognition

-

Detailed component/batch/lot tracking

-

Individual error catalog handling