High-power Laser Diode Assembly

Where would we be without laser diodes

and the myriad devices that are made with them?

The laser diode is one of the most common devices used throughout photonics. The micro-assembly process calls for the placement and bonding (align-&-attach) of single emitters, or multiple laser diodes (stacked or complete bars), the placement, active alignment and bonding of necessary micro-optical elements, subsequent device testing, and ultimately packaging and quality control.

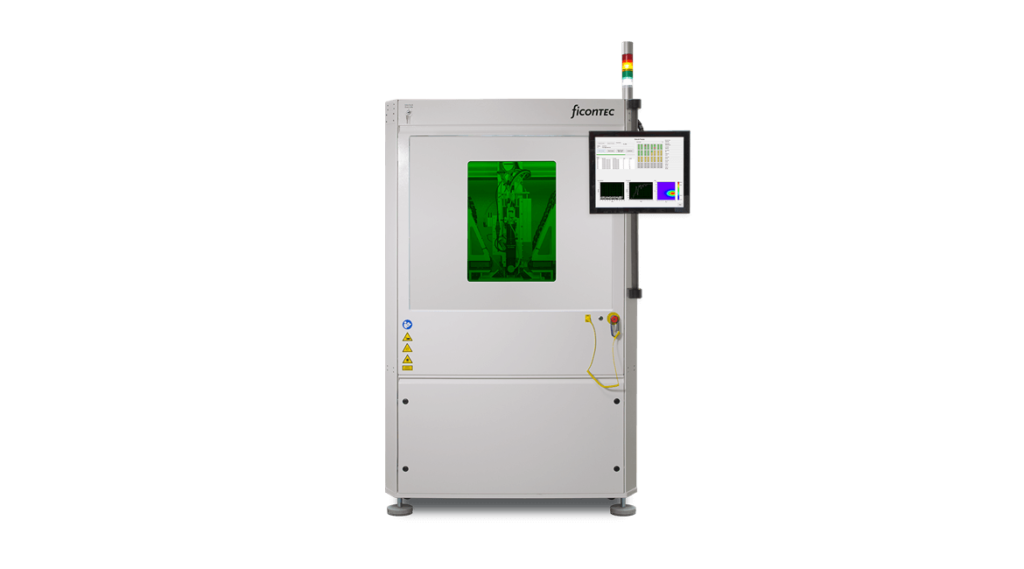

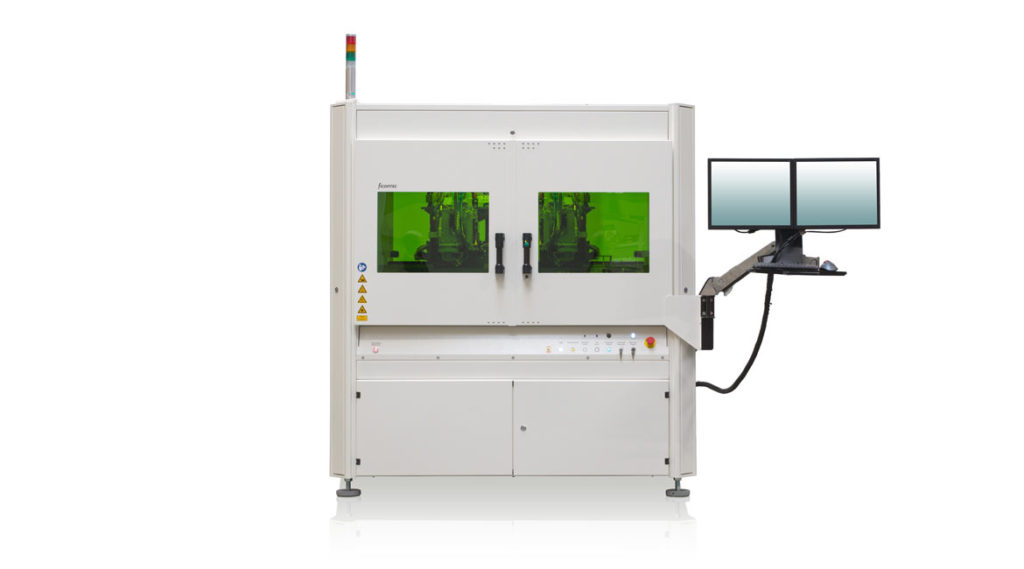

ficonTEC’s machine systems are capable of all the steps necessary for assembling laser diodes, even high-power devices. Multiple in-line systems can be configured to address entire process segments.

Have special requirements? Speak to one of our team:

Contact usKey Manufacturing Capabilities

-

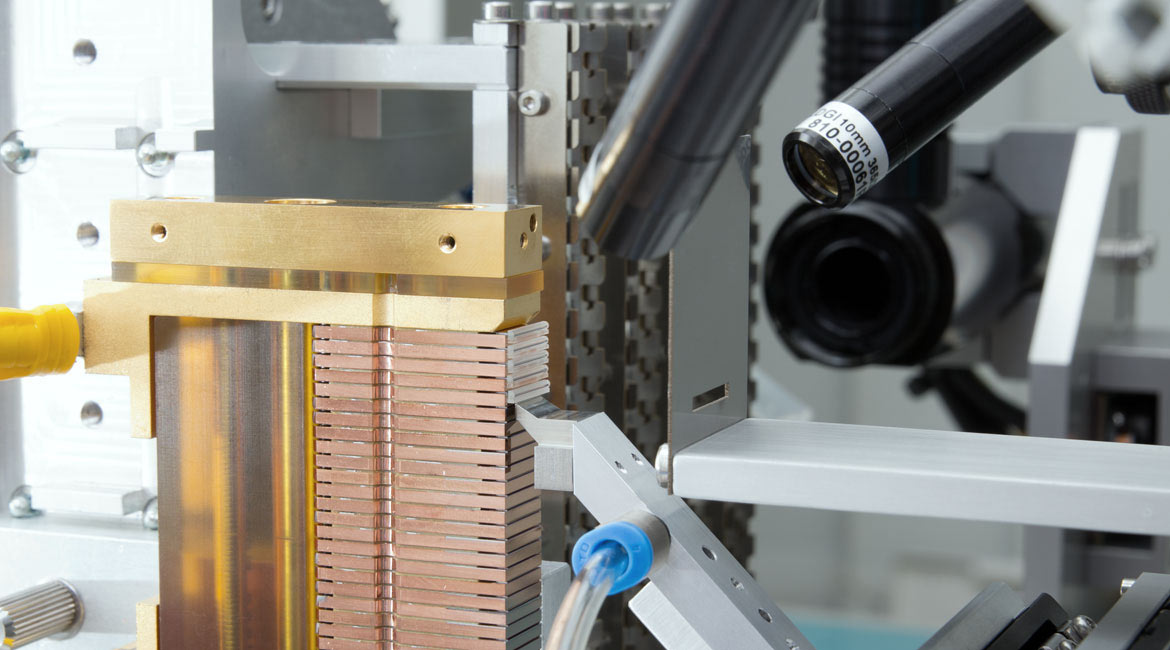

Pick-&-Place and assembly of laser diodes as single emitters or as complete stack of laser diode bars

-

Bonding via eutectic soldering, (UV) epoxy adhesives, or laser soldering

-

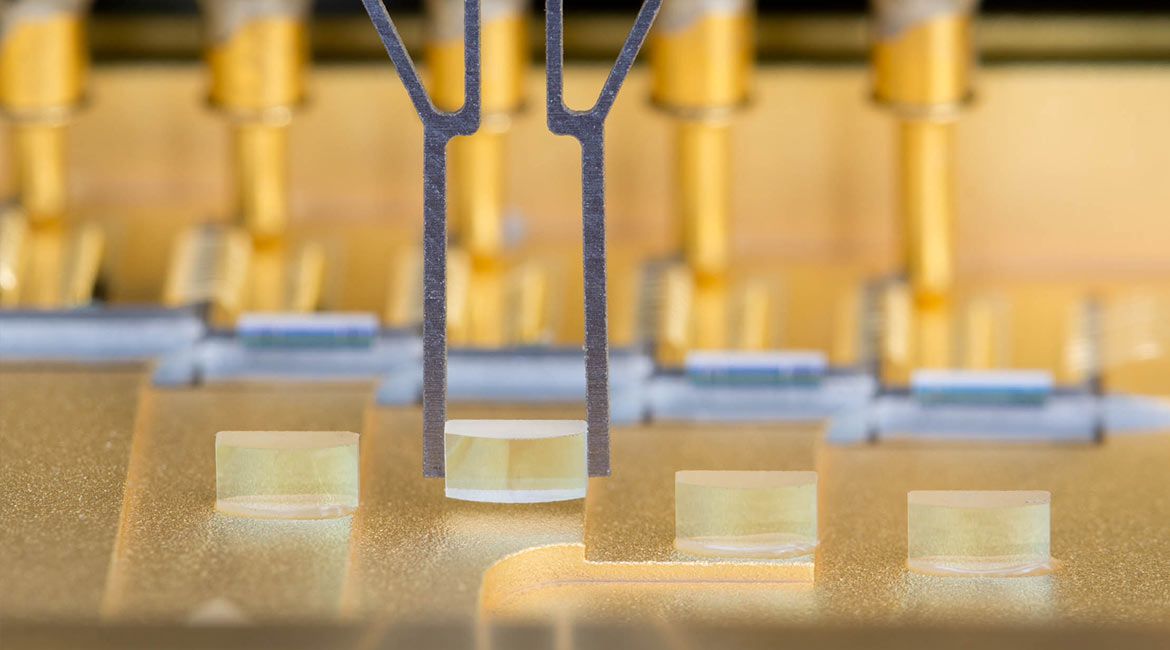

Placement, alignment and bonding of associated micro-optical components (fast-axis and slow-axis collimation)

-

Pigtailing of output fibers

-

LIV testing and beam characterization

-

Full packaging assembly

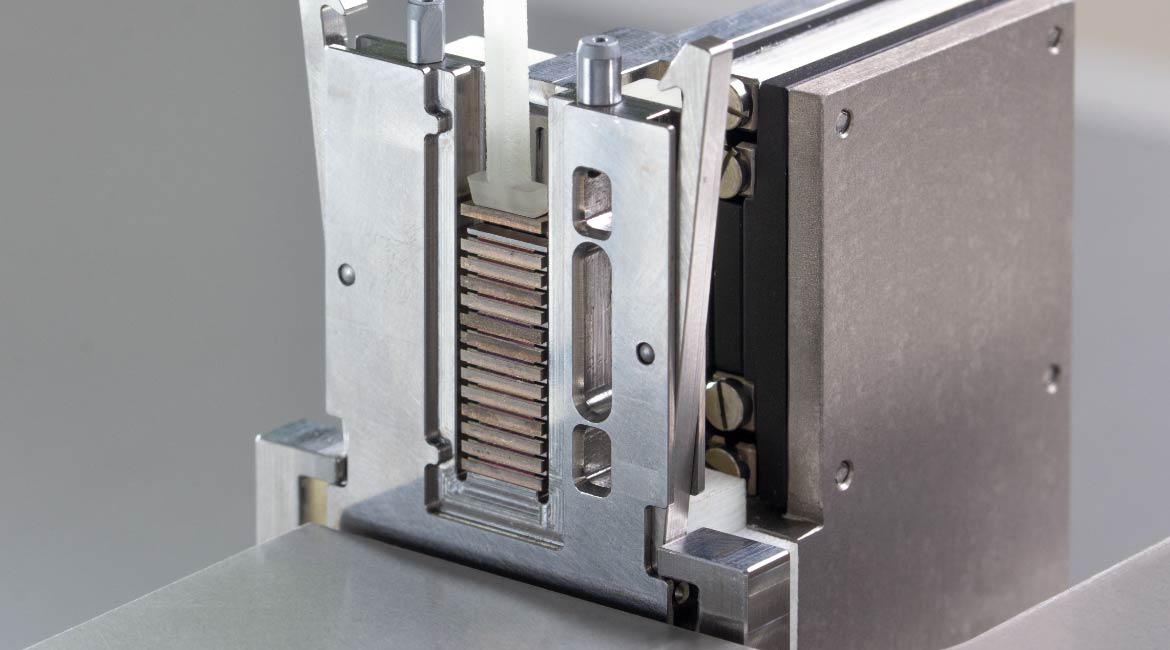

Multiple element/emitter align-&-attach

Staggered stacking of laser bars

Aligning fast-axis lenses onto stacked bars

Laser microwelding

-

High-precision multi-DOF alignment engine

-

Automated attachment of collimator lenses

-

Signal auto-locking

-

Closed-loop active alignment using beam profiling

-

Precision epoxy dispensing

-

Active tracking epoxy shrinkage compensation

-

Extended operator-less production

-

Flexible, easy-to-use software platform

More information

Relevant machine types:

ASSEMBLYLINE, STACKLINE, LASER WELD

Die-level photonic device assembly

Precision laser bar stacking