You are currently viewing a placeholder content from YouTube. To access the actual content, click the button below. Please note that doing so will share data with third-party providers.

More InformationSeptember 2020

ficonTEC and PHIX Photonics partner to enable high-volume manufacturing

PHIX B.V. of Enschede, The Netherlands, is a Dutch packaging foundry that assembles their customers’ photonic integrated circuits into complete modules. As these modules evolve from initial prototypes into mature products, the manufacturing volumes become much larger and a higher level of automation is required. This aspect of photonic device manufacturing is often unjustifiably overlooked, although assembly and test are undeniably critical steps in product development and, ultimately, in their commercialization.

In order to further enhance their ability to scale up production to better match customer needs, PHIX has commissioned ficonTEC Service GmbH of Achim, Germany, to build flexible machine systems for a range of chip-to-chip assembly tasks. As the market-leading machine manufacturer specializing in equipment for assembly and testing of photonic devices, ficonTEC’s strong expertise in realizing advanced assembly automation via hardware capability and software control is highly complementary to PHIX’s extensive process knowledge.

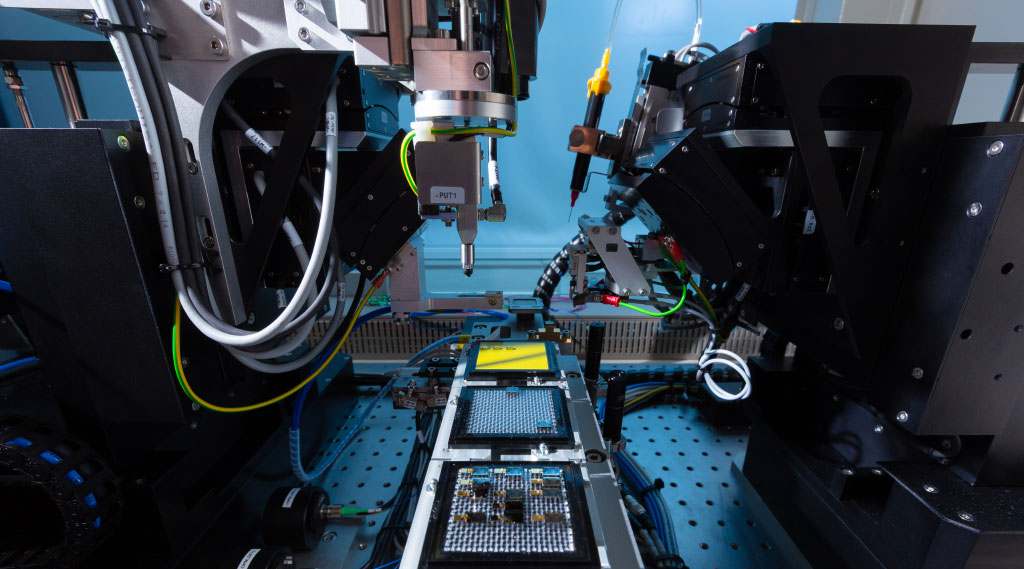

The machine system recently delivered to PHIX currently performs automated integration of multiple photonic integrated circuits (PICs) for chiplet manufacturing. The chips are actively aligned through optical feedback loops or by actively powering up one of the chips during assembly. Two 6-axis stages simultaneously position a fiber array and optical chips (waveguides, PICs) to one another with sub-micron precision. Subsequently, the required elements are bonded using UV-activated adhesive, resulting in a post-bond accuracy of less than 250nm.

This partnership goes far beyond the delivery of a machine, as PHIX also offers process development and manufacturing services on ficonTEC equipment to ficonTEC customers. This process development, testing and scalable production can either take place at PHIX or at the customer’s own location. This provides photonics-enabled device manufacturers with unparalleled support, flexibility, scalability and peace of mind. Furthermore, this long-term character of the collaboration between ficonTEC and PHIX paves the way towards highly automated production facilities that can meet the output demanded by the rapidly growing photonics market, now and in the future.

More information is available by contacting ficonTEC or PHIX directly.

Contact usAbout ficonTEC Service GmbH

ficonTEC is the recognized market leader for automated packaging and testing machine systems for high-end opto-electronic components and integrated photonic devices. Considerable process capability and dedicated assembly technologies have been accumulated over more than two decades of serving the needs of a broad selection of industry segments – including telecom and datacom, high-power diode laser assembly, sensing from bio-med to automotive, micro-optics, fiber-optics and more. ficonTEC’s flexible and scalable automation options enable customized assembly and test solutions suitable for early device development, for new product introduction (NPI), and all the way up to high-volume manufacturing (HVM) – regardless of whether for contract manufacturing or for in-house corporate R&D and production.

About PHIX B.V.

Starting its operation in 2018, PHIX is a European-based provider of automated photonics assembly services with its main facilities in Enschede, The Netherlands. We aim to become a world leader in the supply of PIC-based components and modules in scalable production volumes. We offer fiber arrays and assembly services for all major technology platforms, such as InP, Si, LiNbO3 and SiN. Naturally we are specialized in hybrid integration of multi-chip assemblies. PHIX provides a one-stop-shop from design to volume production of PIC modules.