ficonTEC Service GmbH of Achim, Germany, and Coherent Solutions Ltd. of Auckland, New Zealand, have entered into a collaborative partnership to advance electro-optical measurement capability for use in volume testing within the manufacturing cycle of integrated photonic devices (PICs). As optical and electrical technologies become more miniaturized, complex, and increasingly integrated with one another’s underlying architecture, the more inefficient and frustrating it is for process engineers to implement separate electrical and optical test and qualification procedures. To avoid this, engineers require fully-automated systems that can perform complex precision alignment and assembly, as well as combined electro-optical I/O measurements for complex integrated photonic devices – from singulated dies, through to wafer-level and even up to fully-packaged devices. According to Ignazio Piacentini, Business Development Director at ficonTEC, “Wafer-level testing of PICs differs substantially from that of conventional semiconductor wafers and requires the integration of three major ingredients: Firstly, high-accuracy, sub–µm optical positioning with fast-active alignment capabilities. Secondly, some form of combined electro-optical probe head, and thirdly, modular high-channel-count instrumentation. ficonTEC and Coherent Solutions already provide the necessary capabilities for the first and last ingredients, and together we are actively researching electrical/optical probe head concepts.” Coherent Solutions’ broad portfolio of photonic test and measurement instruments includes a line-up of modules for the popular PXI platform that leverage National Instruments’ established LabVIEW graphical programming environment. As ficonTEC’s PCM (ProcessControlMaster) software is also based around LabVIEW, integration of the two is seamless and enables the creation of sophisticated and fully-automated test solutions to match individual requirements. Alternatively, to achieve the same goal within non-LabVIEW and alternative instrumentation environments, Coherent Solutions additionally offers the same optical measurement capability in a range of compact, modular benchtop and IOT-focused test equipment that can be equally well interfaced to ficonTEC’s process control software. Either approach can be flexibly used by manufacturers to speed up development and production of the latest photonic integrated circuits and devices. Andy Stevens, CEO of Coherent Solutions says, “The last 20 years of investment into technology for optical communications is now spawning new capabilities and products in new applications and markets, which in turn encourages further development and innovation. We are fortunate to support this innovation and are incredibly excited to work with ficonTEC on new automated test and measurement solutions for manufacturers. Our complementary product platforms and design philosophies enable rapid customization and deployment and provide a clear upgrade path as technology advances and products evolve. For customers, this increases ROI and helps them bring new products to market faster and cheaper. Together, we will provide customers with unique products and unrivalled value and support.” Torsten Vahrenkamp, CEO of ficonTEC Service added, “The collaboration with Coherent Solutions could not come at a better time, as a number of our current activities are geared to further improving performance and capability for our new, next-generation assembly and test systems. By integrating Coherent Solutions’ innovative optical instrumentation and software into our modular machine architecture and process control software, respectively, we take a significant step forward in our continued and growing support for integrated photonics developments worldwide.” The two companies are initially focusing their sights on manufacturers of modules and components for telecom and datacom, and on systems for testing high-density VCSEL systems as used in 3D optical sensing/imaging applications, such as for automotive LIDAR and for face recognition modules found in smartphones. ficonTEC and Coherent Solutions will display the initial results of this collaboration with a live demonstration of a fully-automated photonics test system at NIWeek in Austin, TX/USA, from May 20-23, and again at Laser World of Photonics in Munich, Germany, from June 24-27, 2019. For more details contact either Coherent Solutions or ficonTEC Service. Ignazio Piacentini can be reached directly at ignazio.piacentini@ficontec.com. Andy Stevens can be reached directly at a.stevens@coherent-solutions.com. About Coherent Solutions Coherent Solutions is a world-leader in photonics test and measurement. Our expertise in harnessing, manipulating and measuring the physical properties of light enables us to solve complex test and measurement challenges across a broad range of applications and industries. We design and build an expanding portfolio of benchtop and modular test instruments to meet the needs of scientists, engineers, and manufacturers around the world. For more information visit www.coherent-solutions.com. About ficonTEC Service ficonTEC is a recognized market leader for automated packaging and testing machine systems for high-end opto-electronic components and PICs (photonics integrated circuits). Considerable process capability and dedicated assembly technologies have been accumulated over more than two decades of serving the needs of a broad selection of industry segments – including telecom and datacom, high-power diode laser assembly, sensing from bio-med to automotive, micro-optics, and more. ficonTEC’s flexible and scalable automation options enable customized assembly and test solutions suitable for early device development, for new product introduction (NPI), and all the way up to high-volume production facilities – regardless of whether for contract manufacturing or for in-house corporate R&D and production. Product and company names listed are trademarks or trade names of their respective companies.Mixed-signal electro-optical

measurements for integrated photonicsficonTEC Service and Coherent Solutions to collaborate on ground-breaking measurement systems for photonics assembly and test

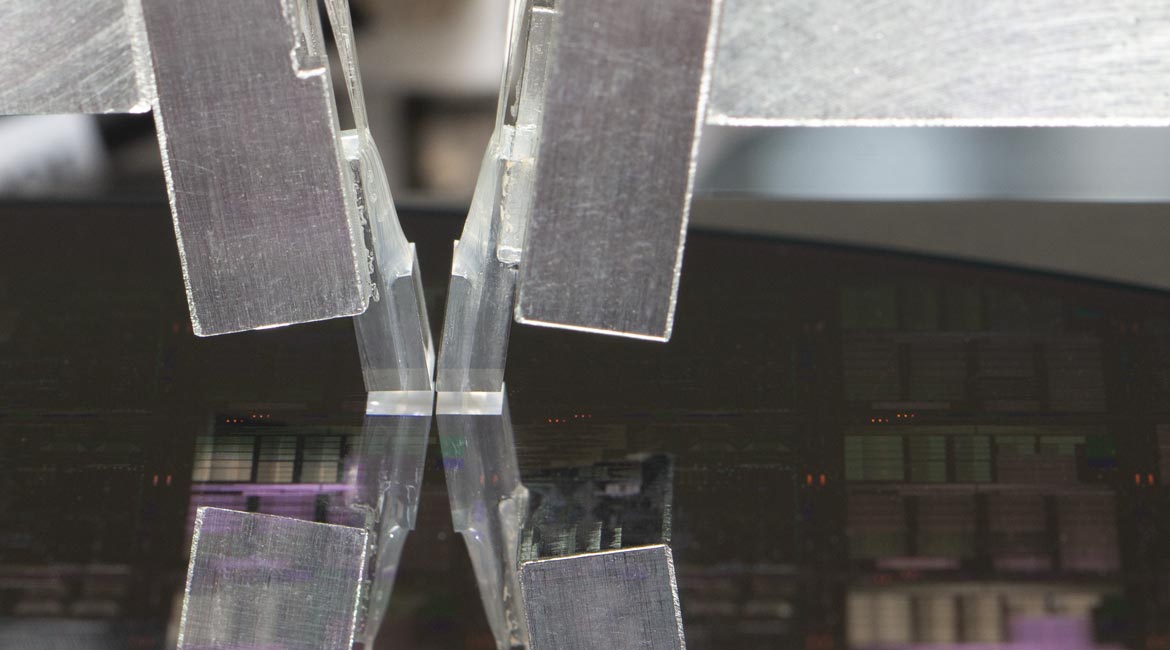

Multi-fiber optical I/O probes positioned over the wafer

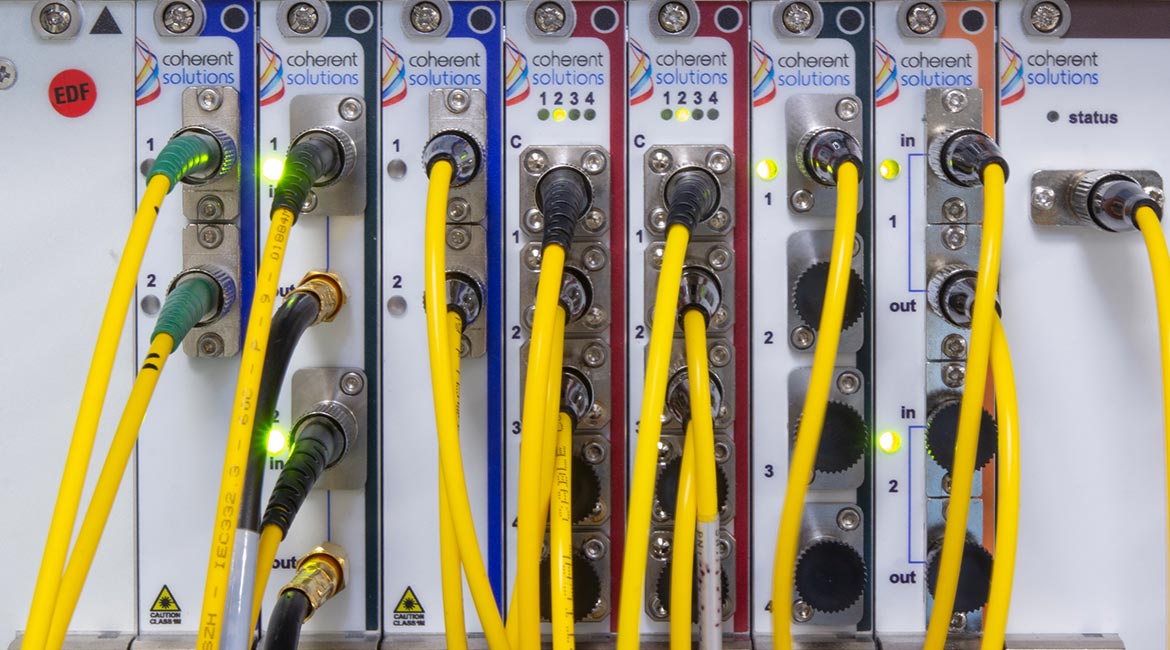

Details of the optical PXI front-end modules

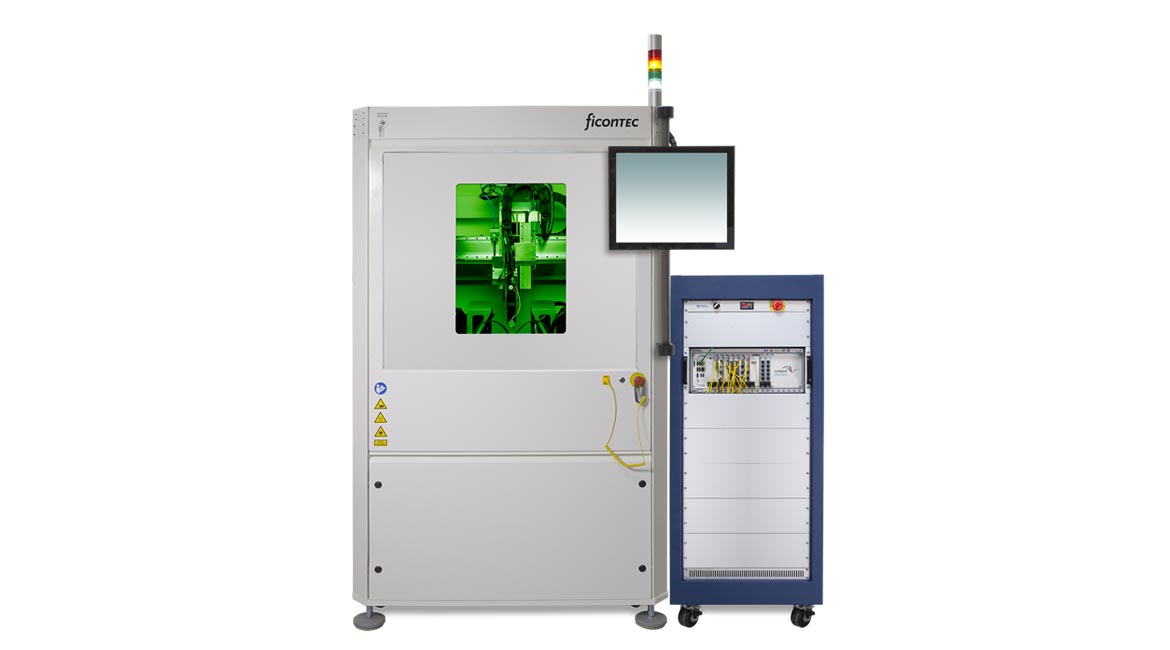

PXI-based, fully-automated wafer-level test demo-system